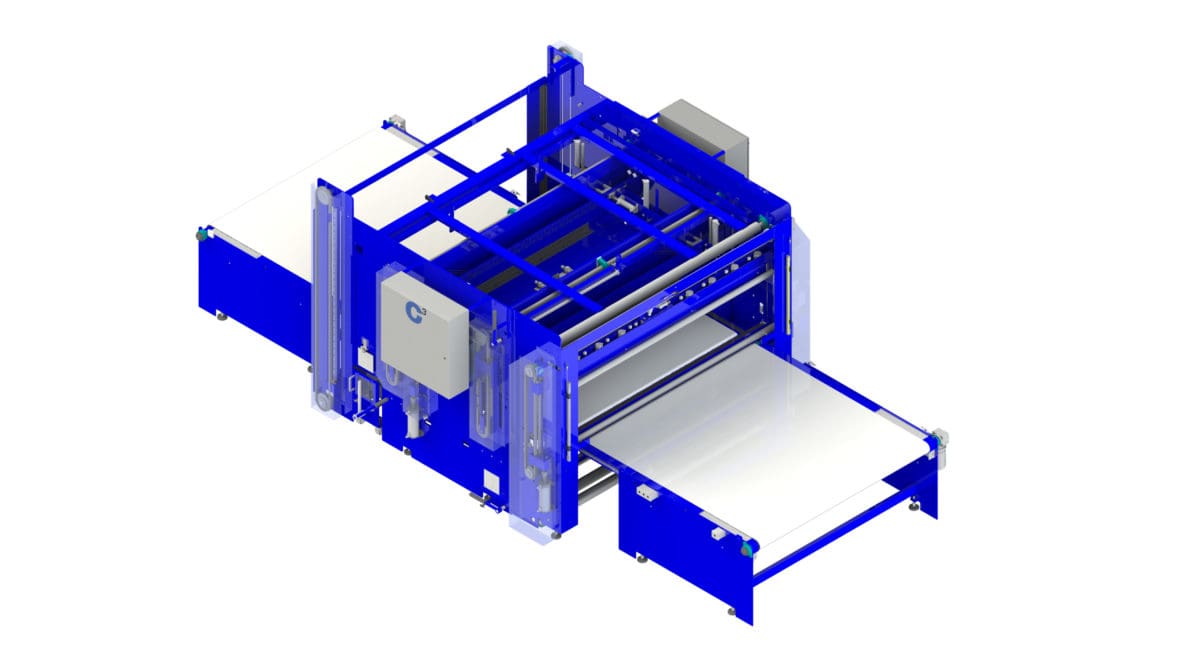

Product Overview

Quickly Bag Products For Shipment

The auto-bagging machine is engineered for durability, ease of use, speed, and consistency. By packaging up to 180 products per hour, its throughput is ideal for mattresses, cores, toppers, bases, and boxsprings. This machine uses only slight compression and is your solution for packaging products not suitable for traditional compression.

C³'s Package-First Methodology

Our package-first methodology stays standard even when we’re not using full compression. Some products just aren’t suited for compression packaging, which calls for an auto-bagging solution like what’s found with the AB9065. Here is an example of an ideal package created with this machine.

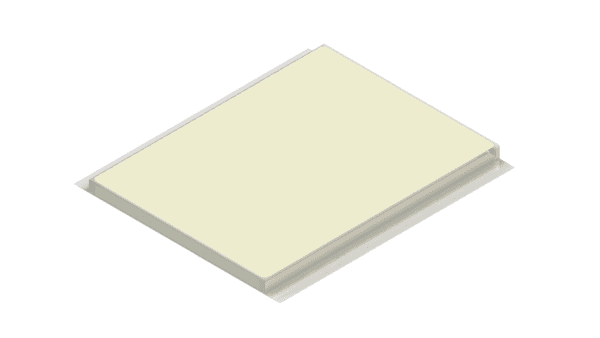

4-Layer King Mattress

This king-sized mattress has four all-foam layers. When packaged with the AB9065, it maintains its dimensions in the bag. Because this mattress is all-foam, it’s likely slight compression was used to package it.

Frequently Asked Questions

This auto-bag system uses only polyethylene film at one width to package products.

If you’re hand-bagging your products that can’t be compressed, the biggest benefits you’ll see is the speed and consistency of packaging.