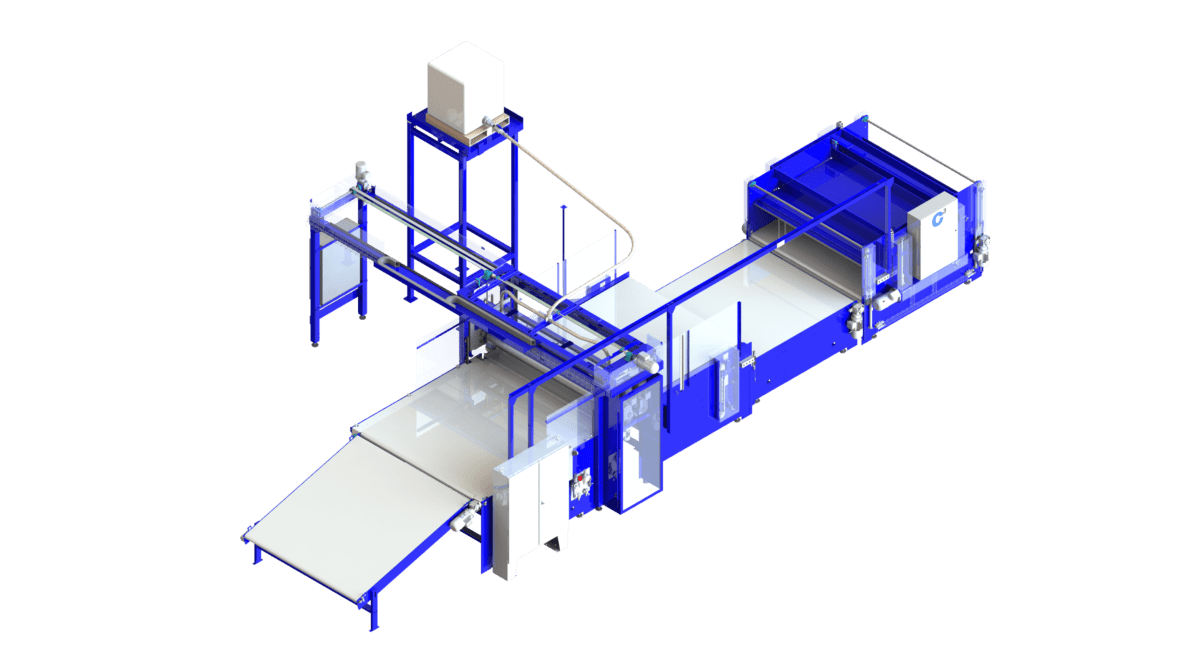

Product Overview

Fast Throughput, Accurate Placement, & Protective Ergonomics In One Lamination System

This lamination system provides a balanced use of automation and operator involvement at the build section. The machine handles glue application and lifting and placement of the layers, now operators simply need to make easy waist-height adjustments before sending it off to the tamp press. It is an ergonomically-friendly design with the fastest throughput.

Efficient Automation with C³ Lamination

The LCN1250 takes the best tools of automation and pairs them with the quick adjustments only an operator can do. It protects your builds from error and your operators from injury.

Every drop of glue should be used to adhere the layers of your build, not create a mess on your floor or of your products. C³’s lamination works towards efficient use of glue to save you money in consumables and in overall production efficiency and quality.

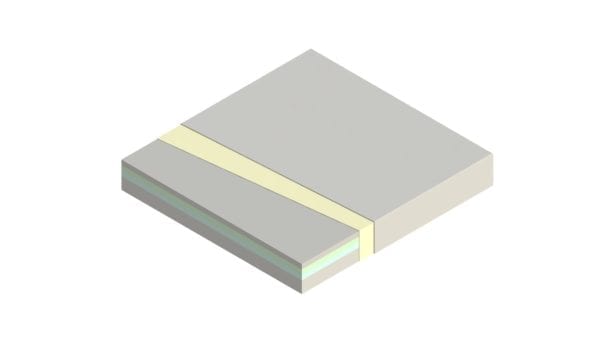

Example Lamination Recipe

For a standard queen, 3-layer foam mattress, we follow the following example recipe.

Glue per layer: 6 g/ft2

Tamp Press Recipe: 2 presses at 70% compression for 5 seconds

Total Throughput: 18 seconds

Using gap control, the rollers will meet the foam at the right height to ensure each layer reaches the necessary glue coat weight. This prevents from too much or too little glue application.

How The Lamination System Works

Glue

C³ application rollers apply glue efficiently at a perfect coat weight with automated gap control.

Place

Product is placed within 1-inch of accuracy. Operators can man the build table to manually adjust layers if needed.

Adjust

This unique design allows operators to make last-minute tweaks to the build without any lifting.

Tamp Press

The tamp press secures the glue’s bond and speeds cure time.

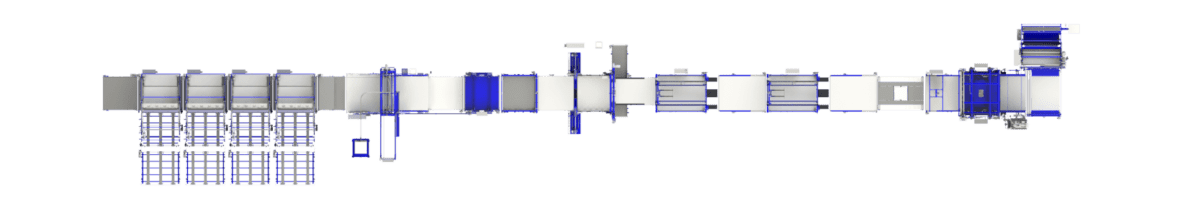

Take Advantage of The Lamination Machine's Biggest Automation Benefits

Because of its efficiency, throughput on this lamination system is rapid-fire. Here's how manufacturers amp up their machine to take full advantage of its features.

Fast Throughput

Automating with the LCN1250 brings the fastest machine throughput to your production.

Room For Adjustments

The build table on the lamination system allows for operators to make small adjustments to a build or introduce a pocket coil or special layers to the line, allowing for variability.

No Heavy Lifting

With the LCN1250's merge table, the machine places layers onto a laminate build so there's no lifting involved in production.

Ready To Automate Your Production?

Frequently Asked Questions

- Foam or latex layers

- Pocketed coil layers

- Convoluted or contoured layers

- Scrim material and most nonwovens

Yes! You’ll need to opt for the hot melt glue add-on and squaring section when looking to purchase.

Operators using the LCN1250 never lift at the build station, only perform small finger adjustments. The placement is within a 1-inch accuracy, so adjustments are minimal. This allows for improved ergonomics of your facility.