Product Overview

Perfect Edges For All Products

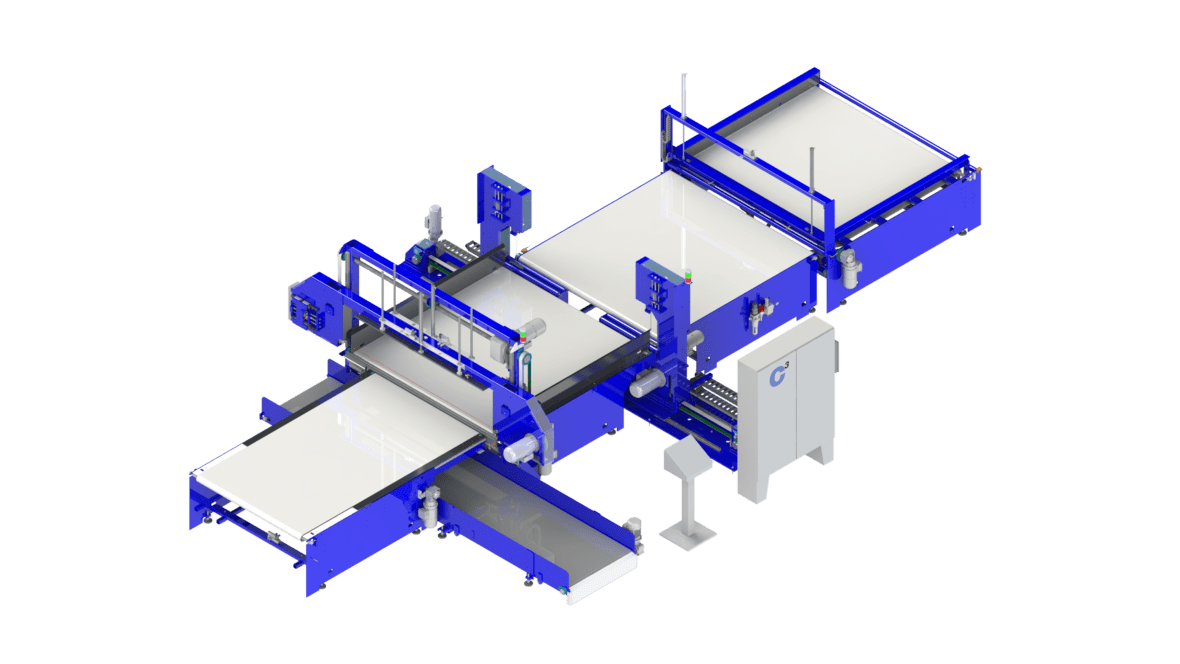

C³ trimming machines consist of squaring section, conveyor, trim saw, and waste disposal units. The system trims mattresses to spec or splits king-sized beds to twins without interrupting the flow of production. C³ trim systems can be used before or after lamination.

How The Trim Machine Works

Square

The laminate is squared on two flush sides to ensure a perfect cut.

Trim

The saw blades trim the laminate to spec with accuracy within 1 cm. Durable blades can even slice through wet glue without excessive wear.

Remove Waste

Automatic waste disposal cleanly removes waste from the product and away from the line.

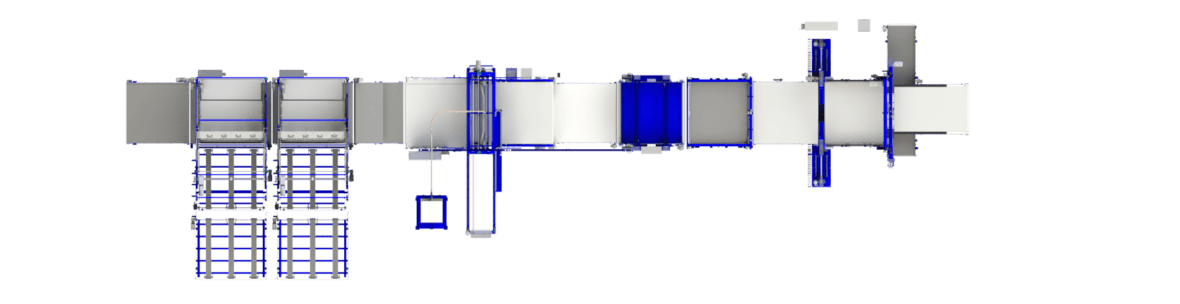

Where Trimming Machinery Works In Production

Vertical trimming lines fit into production before or after lamination. There are multiple options for customizing the trim section based on your products. Here's an example of where it fits in manufacturing.

Straight Pass-Through

When lamination and trimming are in line, the product can maintain its position throughout the line.

Trim After Lamination

Trimming after lamination guarantees a perfect core every time. Consider this layout for a new production line.

Configuration Options

The trim line has options to include sections for splitting king cores into twins and for waste disposal. You'll choose the configuration that best suits your facility layout.

Ready to build your production line?

Frequently Asked Questions

Trimming after lamination takes the pressure off operators and their accuracy building cores during lamination. It also guarantees you have perfect edges before putting on fire socks and covers. Trimming after also makes it easier to scale to full automation of your lamination section.

The blades on these trim systems can cut within 1 cm of accuracy.

The trimming systems can handle foam and latex products.