Product Overview

A quick and clean way to apply glue to foam rails for beds with pocket coils

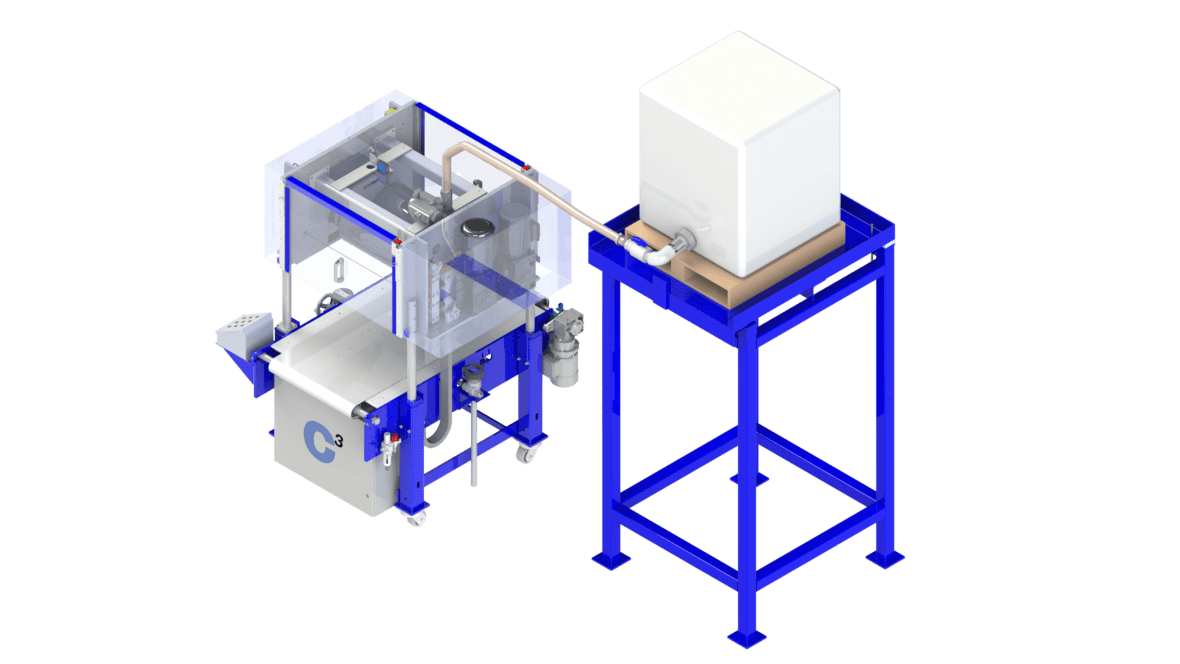

Manufacturers install this mattress rail lamination system to efficiently apply glue to foam rails outside of the main production line. Operators use this machine to pre-build pocket coil encasements. Taking advantage of roll application at this step allows for clean, accurate glue coating with less mess and better bonds.

Efficient Lamination For Foam Rail Encasements

Applying glue to foam rails is a labor-intensive process. When using spray glue, it’s even more labor intensive and messy. Installing a mattress rail lamination machine allows for pocket coil encasements to be pre-built before laminating the other layers of the mattress.

For manufacturers looking to add encasement capability to their lines, this machine is an inexpensive addition to improve your facility’s capabilities.

Foam Rail Encasements

When pocket coil beds are built with foam rail encasements, they can be pre-manufactured to run more efficiently in your production. This product consists of a layer of pocket coils at the following specifications. The rails are glued using the rail lamination system and the full bed is laminated using full-sized C³ lamination machinery.

Queen Pocket Coil With Encasement Build Specs:

Layer 1: 4-inch base foam layer

Layer 2: 2-inch foam rail encasement with pocket coil

Layer 3: 1-inch comfort layer

Layer 4: 1-inch comfort layer

How The Rail Laminator Works

Adjust For Production

Adjust the rollers to meet the product height with manual controls.

Apply Glue

The same rollers, application process, and glue provide consistency across your operations when used with other C³ lamination equipment.

Build The Encasement

Rails with glue are taken by operators and used to build an encasement with a base foam.

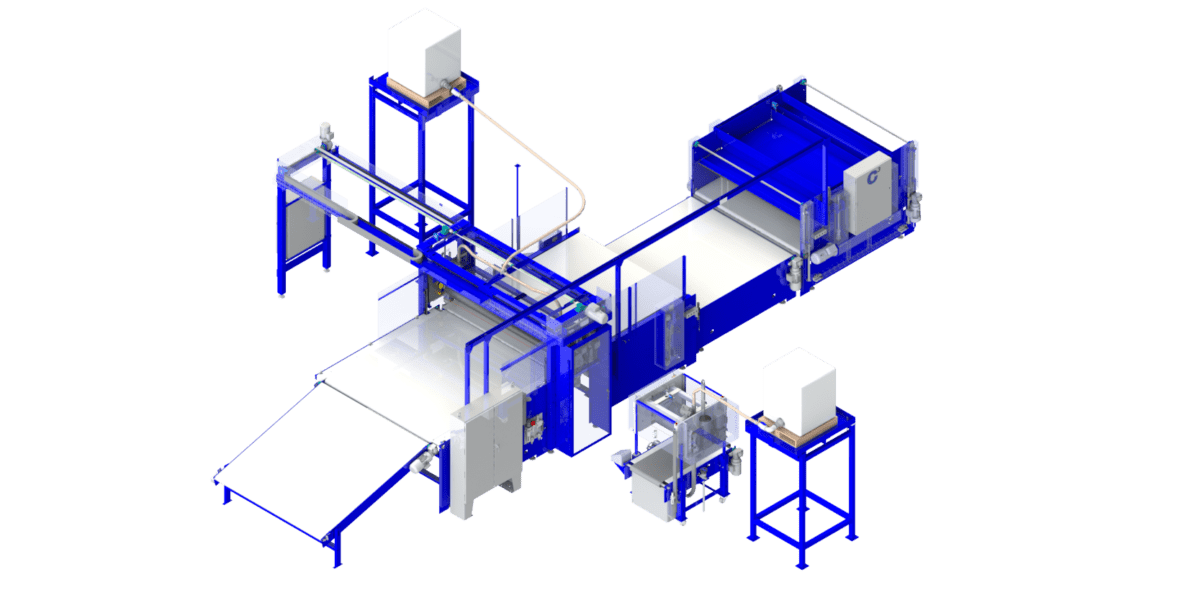

See Where The Rail Lamination System Fits In Your Line

The rail lamination system works best when used in conjunction with a full lamination production line. Here, it takes advantage of accumulation for a final build.

Produce Product Efficiently

Pre-manufacture the encasement layer for efficient final production.

More Production Capability

Add capability to your facility without a major investment or alteration to your existing machinery.

Take Advantage Of Consistency

Use the same glue and application process to laminate foam rails as you would in full production.

Ready To Add To Your Automation?

Frequently Asked Questions

The rail lamination system works with any water-based adhesive including acrylic and latex glues.

The machine can be run with one to two operators.