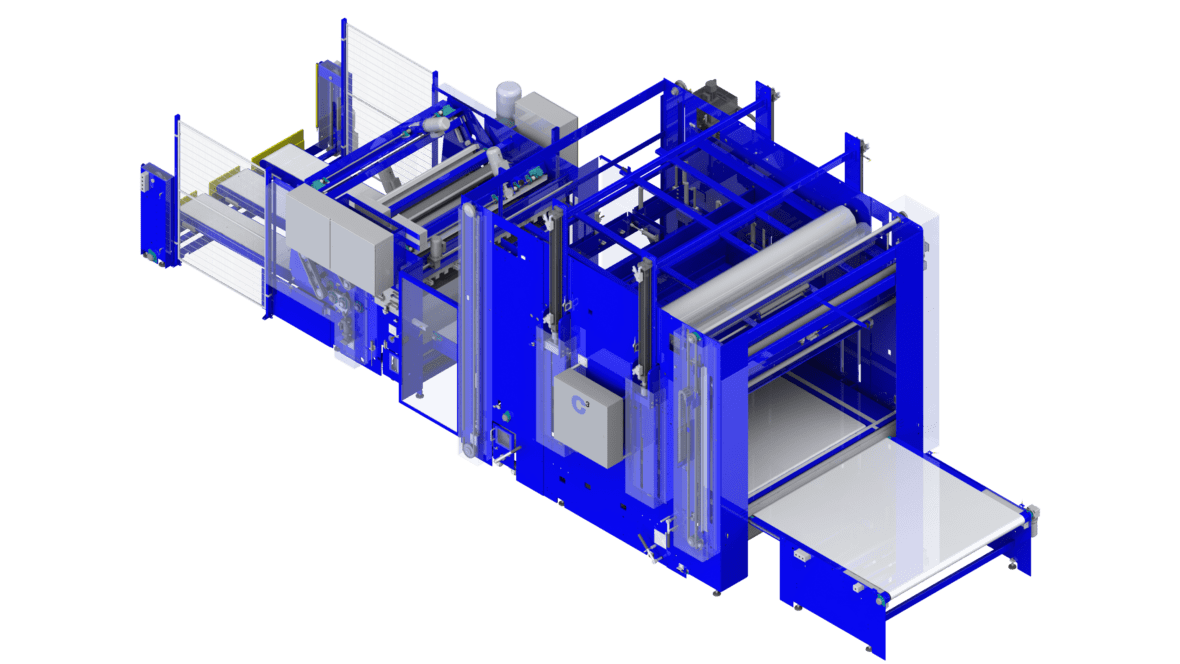

Product Overview

Compression Packaging Solutions For Polyurethane Foam Blocks

The block compression machine compresses and roll-packages foam blocks and stacked cut layers with a volume reduction ratio of 22:1. Manufacturers install this system when they're looking to save space in inventory, make handling foam blocks more efficient, and reduce shipping costs per unit.

C³'s Package-First Methodology

Before selecting a packaging machine, you must consider your product first. What is it made of? What kind of package is ideal for your operation? How will you ship it? How long will it stay packaged? How will your customers handle it upon receiving?

C³ works with our customers to find the ideal packaging options for their products. Then we select the best machine for the job. Here are examples of ideal packages created with this machine.

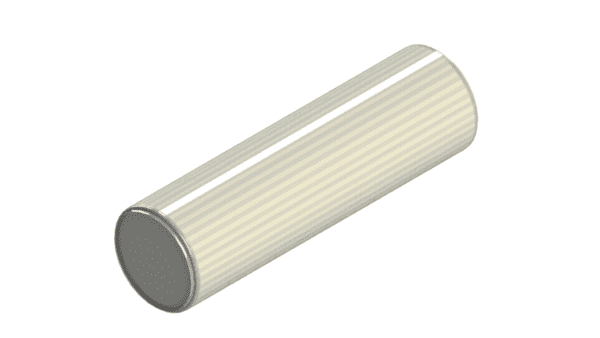

Conventional Foam Block

This conventional foam block has a density of 1.85 lb/ft³. When packaged with the BC2496, it reaches the following dimensions.

Final Package Dimensions:

Diameter: 25 in (635 mm)

Length: 84 in (2134 mm)

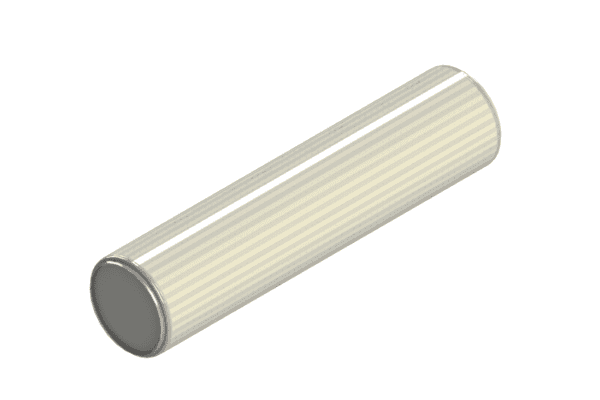

Visco Foam Block

This visco foam block has a density of 2.8 lb/ft³. When packaged with the BC2496, it reaches the following dimensions.

Final Package Dimensions:

Diameter: 20 in (508 mm)

Length: 84 in (2134 mm)

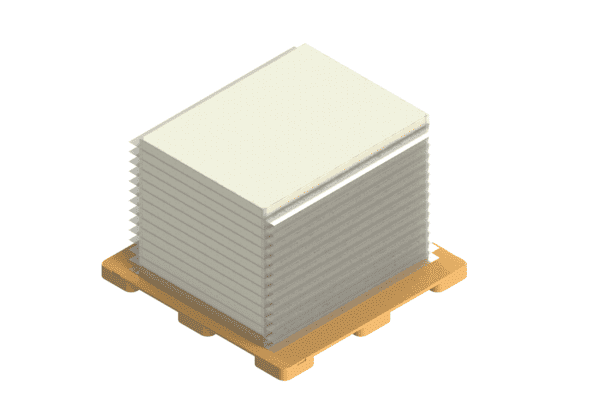

Alternative: Flat Packaging

Flat packaging makes kitting product easy and maximizes how many blocks you can fit on a pallet for shipment. Belts or banding may be required.

Final Package Dimensions:

Product: 60 in x 80 in mattress (1524 x 2032 mm)

Compressed Height: 4 in (102 mm)

Final Pallet Height: 60 in (1524 mm)

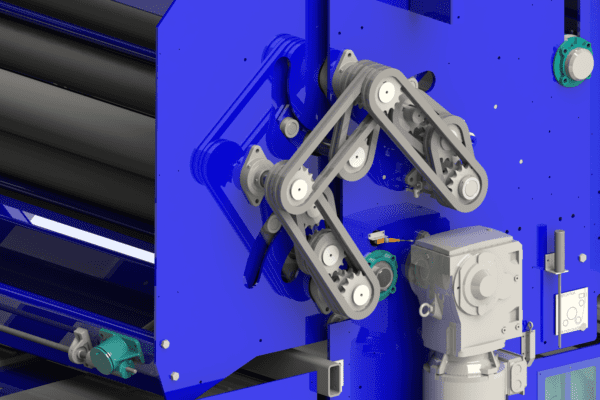

Block Compression Machine Features

Compress

The tamp press compresses product with limited distortion due to its four-corner control. This balance reduces the risk of product damage and protects the machine.

Seal

C³-engineered heat seal bars lock in compression with polyethylene film. Sealing on all four sides guarantees the package's integrity.

Roll

C³'s roll cage rolls blocks to a set dimension, allowing the product to naturally expand to final specs instead of by force.

More Variability In The Same Machine

As C³ engineers new machinery, we focus on creating a standard design that delivers the most-used functionality. Then, we offer additional components that help you scale your equipment to suit your needs. These add-ons are modular and can be added at any time to your compression packaging system.

Variable Roll Cage for BC2496: BC1600-VC

This option replaces the standard roll cage on the block compression machine with a cage that provides greater tolerance for product variation. This option also provides full automation of the machine, as it includes sensors that measure the specs on the product and computes the ideal compression.

This allows facilities to package products of varying specifications in one machine with limited operator involvement. This roll cage is ideal for operations that handle products with multiple densities, as the cage can scale to suit without damaging the product.

Standard Roll Cage Dimensions: 16-24 in (406-610 mm), selected at one set point (not the full range)

Variable Roll Cage Dimensions: 16-27 in (406-686 mm)

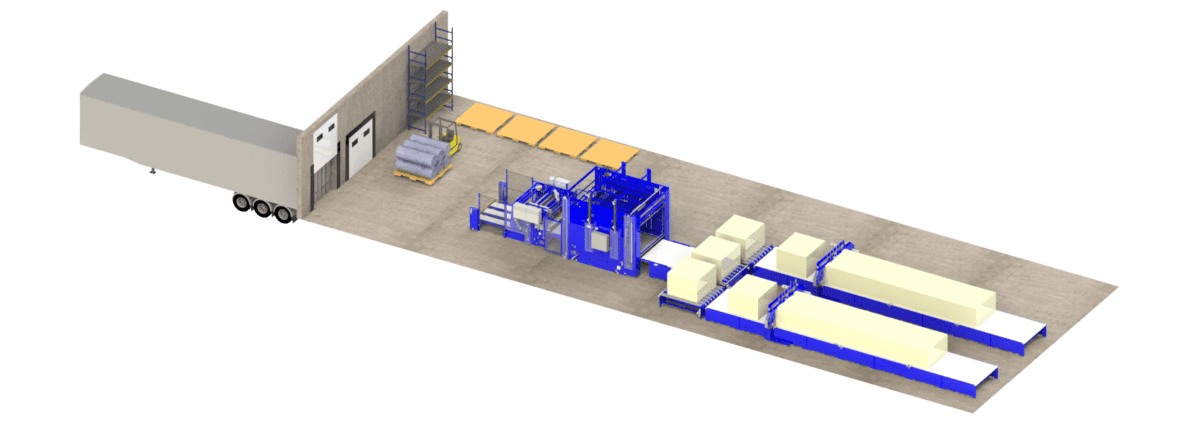

Get The Most From The Block Compression System

The block compression machine fits into a foam pourer's or converter's plant right by the shipping dock. See how it fits into your operation's line.

Ship More Foam, Further

Block compression packaging allows you to ship up to eight times more foam at a lower rate per package.

Pre-Kit Pallets Of Foam

Ship pre-kitted foam on pallets to converters for easy-to-handle inventory management.

Fully Automated With The Variable Cage

Add the variable cage to the machine and reach full automation for packaging your block products.

Ready To Take Block Compression To The Next Level?

Frequently Asked Questions

Here’s an example:

Standard Block: 110 in x 80 in x 50 in (2794 mm x 2032 mm x 1270 mm)

Total on Truck, Uncompressed: 11 blocks

Cost per Package: $227.27

Total on Truck, Compression Packaged: 86 blocks

Cost per Package: $29.07

At C³, we always start with our roll cage calculator. This will consider your product’s dimensions and density, then calculate the best package for those specifications.

This calculator’s logic is incorporated into the variable cage add-on, which makes the machine fully-automated. Ask your account manager for more insight.

Belted machines can cause distortion and damage a block. They also cannot package slit layers of foam, kitted product, cores, or finished goods.

C³’s machine is a straight pass-through design which allows for linear compression. This protects the product and machine from damage or distortion. It also means you can have multiple products in production at a time (total of four!).