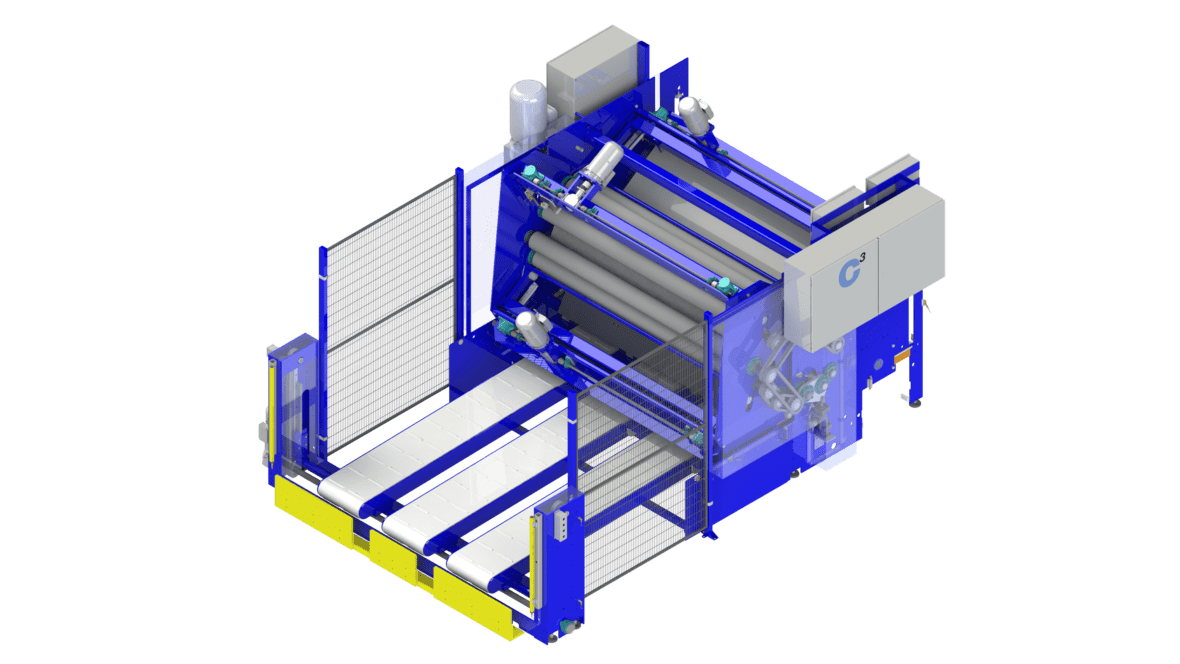

Product Overview

Upgrade Your Roll Cage For More Product Capacity

Adding the variable cage to a block compression system fully automates the machine and allows you to package more product in the same system. This roll cage packages products to diameters within a full range of 16-27 inches, ideal for manufacturers that pour multiple kinds of foam or have a wide range of block sizes.

More Package Options In One Machine

We predict facilities can fit eight times more foam on a truck when using a block compression system. We base this on volume, which allows us to take advantage of different levels of compression to make a perfect package for each block, while also capitalizing on shipping savings.

First, we review each SKU’s specifications in our roll cage calculator to find the best package. Here are a few produced with the variable block roll cage.

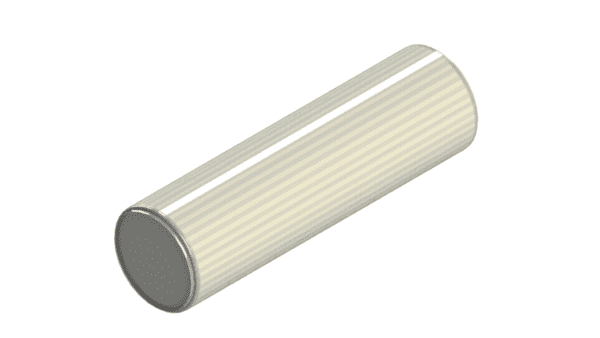

Standard Foam Block

This conventional foam block has a density of 1.85 lb/ft³. When packaged in the variable roll cage, it reaches the following dimensions.

Final Package Dimensions:

Diameter: 25 in (635 mm)

Length: 84 in (2134 mm)

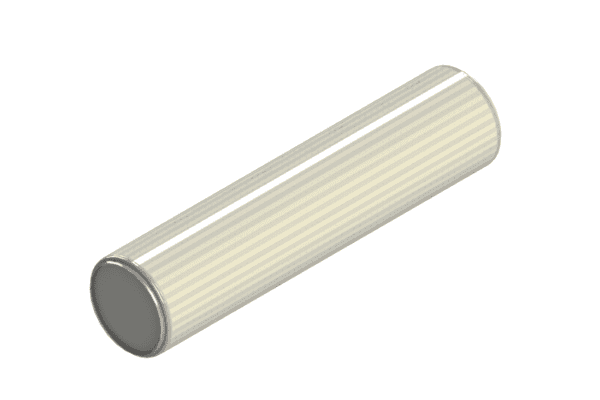

Visco Foam Block

This visco foam block has a density of 2.8 lb/ft³. When packaged in the variable roll cage, it reaches the following dimensions.

Final Package Dimensions:

Diameter: 20 in (508 mm)

Length: 84 in (2134 mm)

Second Visco Foam Block

This second visco foam block has a higher density at 3.25 lb/ft³. This product would not work in a standard cage like the other two example products, but all three will work within a block compression system with the variable cage. When packaged in the variable roll cage, it reaches the following dimensions.

Final Package Dimensions:

Diameter: 21.5 in (546 mm)

Length: 80 in (2032 mm)

Features Of The Block Variable Cage

Smart Sensors

Sensors at the press infeed measure the product dimensions and weight. These inputs are used to calculate the ideal compression level for each product.

Expandable Roll Cage

The variable roll cage packages products within an 11-inch range versus a single set point. Plus, it can expand an additional 3 inches larger than standard.

Hands-Off Operation

With the variable cage, the block compression machine can be fully automated so little to no operator involvement is needed during production.

Frequently Asked Questions

Every cut of foam is different. When we measure weight, length, and height, we guarantee we take into account that specific product’s variables and not just the standard of what it “should be.” When we do this, we can make adjustments with the press and roll cage to allow for better compression to protect that product.

Another great use for the variable cage is to package product based on how long it will be remaining compressed. Just because we can package a product to small dimensions doesn’t mean we always should. If you are packaging foam blocks for a few weeks in inventory, you can package it to the max to save space. However, if you plan to keep it packaged for a couple months and ship it across the country, you might want lesser compression to better protect the product.