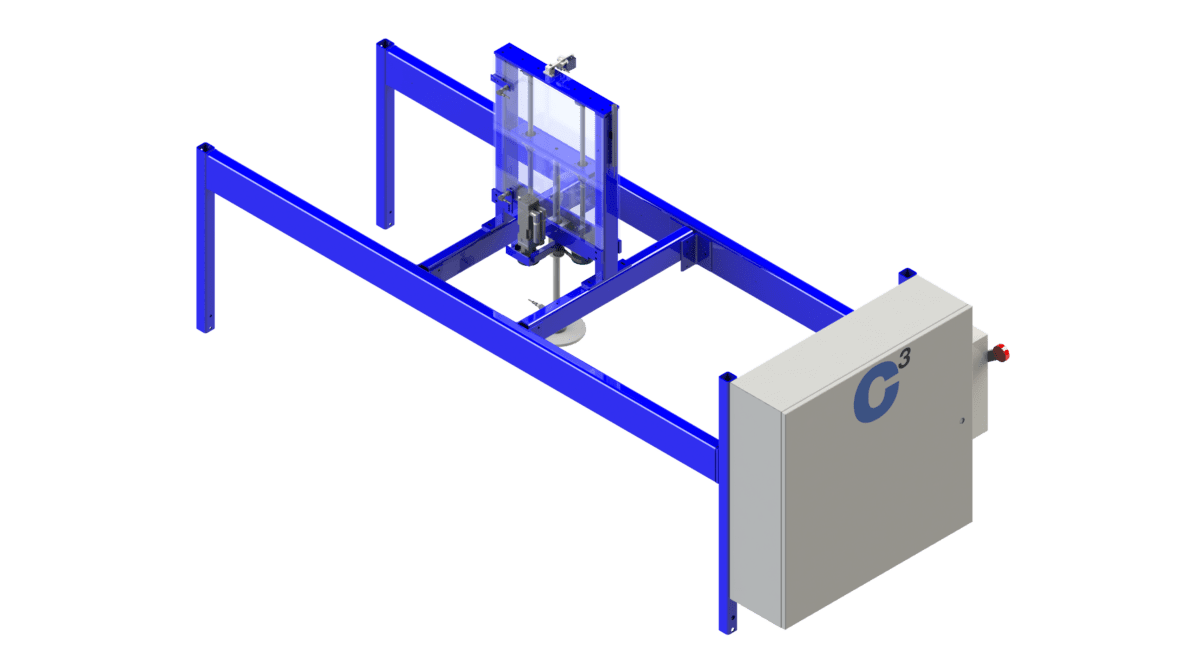

Product Overview

Test Every Finished Product Without Disrupting Your Production

The force deflection test unit measures 200 data points of force as the unit presses into the finished good. The system creates a graph of force over time to determine if the product is in or out of spec for that SKU. By using this system, operators can pull faulty product from the line before it's packaged. This machine doesn't replace standard lab testing, but acts as an in-line solution for testing based on ISO 2439 standards.

How It Works

Run A Test

Run a test on a SKU of product to determine its tolerances. These become inputs and are used to measure against in production.

Monitor Two Points Of Data Collection

The testing plate pauses at two points of compression to determine if it is pass or fail. The first is at 25%, the second at 40% compression.

Determine Faulty Product

By reading the graph, operators quickly see if a product passes the test. If not, it can be pulled from the line.

Gather Analytics

By measuring each product in production, you'll collect a database of info that helps your operation uncover production issues.

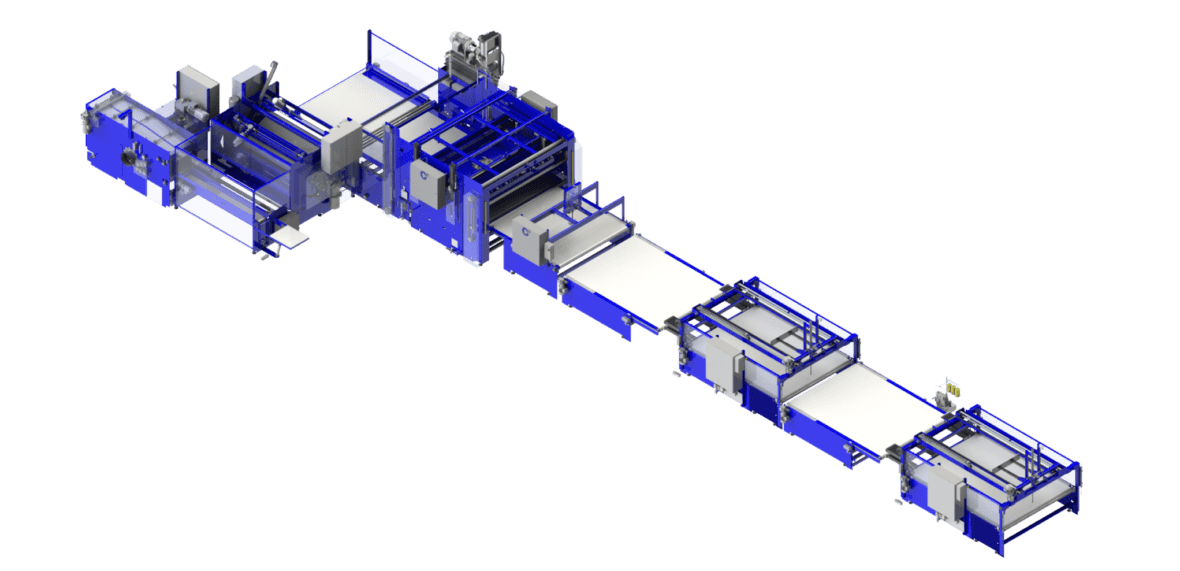

Where The Force Deflection Machine Fits

The force deflection machine works best when installed in front of any of our compression machinery, but can be placed wherever you need it.

Improve Customer Satisfaction

Ship less faulty beds by catching inconsistent product before it's packaged and shipped to your customer.

Spot Trends in Your Operations

Use the data collected from the testing system to determine where bottlenecks originate in your production line.

Improve Product Quality

Determine sources of faulty product such as poor raw materials to ensure your product quality.

Ready to scale with the FD1000?

Frequently Asked Questions

No, this unit is meant to be used as a double-check in production for product that tests 40-60% off the established standard. It does not replace standard lab testing.

We’ve caught errors such as too-tight of covers, low-quality raw materials, and incorrectly built mattresses.

R&D teams sometimes use the force deflection QA system to test if a product can be re-packaged or to determine what kind of compression a product can handle.

We believe most foam and mattress manufacturers will benefit from a FD1000. However, those that see the most return on investment are companies that have high rates of returns due to manufacturing issues.

This machine tests finished goods in line with production. Most lab testing is done on individual parts or sample product, not what is ran daily in production. This testing unit helps to bridge that gap to ensure what you send out the door meets the quality standards you set for your operation.