Product Overview

Mattress Packaging Just Got Smaller & Easier For Customers To Handle

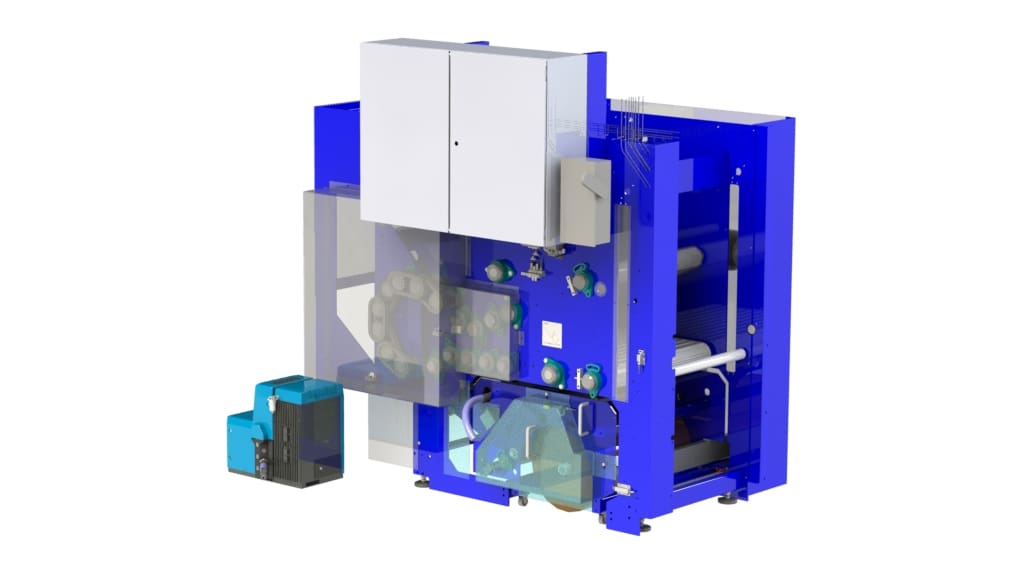

The second roll cage takes the compression of a standard compression folding machine one step further. First the product is compressed, folded, and rolled, then it's rolled again using this cage. The final package can be 45% smaller than the standard. The package created with the second roll cage revolutionizes what's possible with compression packaging.

How The Second Cage Works

Convey The First Roll

The first roll cage loosely rolls the product to width without folding. It then conveys to the second roll cage where scrim is added to help the product push out of the second roll cage.

Roll Again

In the second roll cage, it rolls again to create the smaller package. Density is carefully monitored here to maintain the product's integrity.

Wrapped and Boxed

The product is wrapped in C³'s Paper Wrap or Stretch Wrap holding the cylindrical shape. The final package is placed in a box for shipping.

Frequently Asked Questions

This package is the smallest mattress packaging on the market. It fits nicely on retail shelves and will cost less when shipped on a truck. End customers will find it easier to handle, as it can be lifted and placed in a cart with less effort than a standard bed-in-a-box package.

For now, all-foam beds are best used in the second roll cage. C³ engineers will work closely with you to guarantee your product is suitable for this kind of compression and will fully recover.

Before we set out to package any product, we always do thorough R&D using roll cage calculators and density monitoring. This is part of our package-first methodology and prevents us from damaging your products or overselling you machinery that isn’t suitable for your operation.