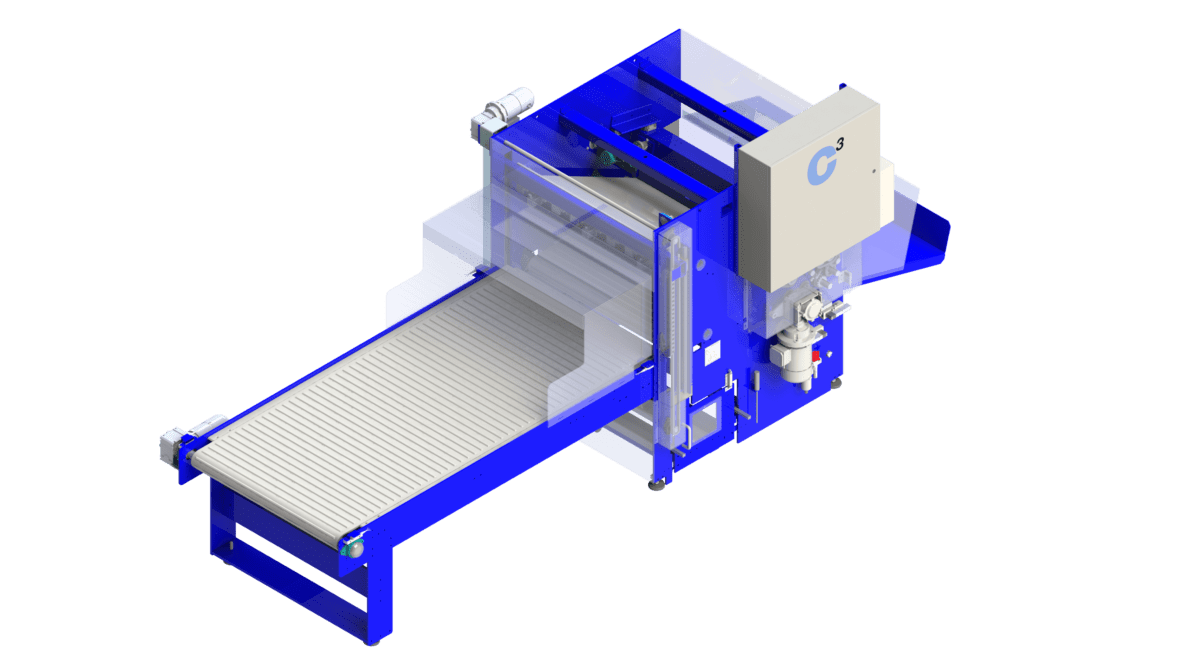

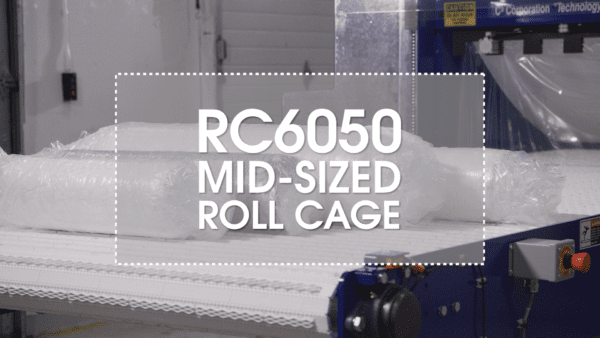

Product Overview

A Versatile System For Medium Sized Foam Products

The mid-size roll cage machine is ideal for manufacturers that produce pillows, pet beds, toppers, wedges, or similar products. It offers the same high throughput rate as the smaller roll cage while allowing for flexibility in product sizes.

C³'s Package-First Methodology

C³ adopts a package-first methodology when engineering the best compression packaging machine for customers’ products. We take into consideration composition, transportation and storage time, packaging, and customer expectations.

We work with clients to calculate ideal packaging options for their products. Then we select the best machine for the job. Here are examples of ideal packages created with this machine.

3-Inch Queen Mattress Topper

To package a topper in this roll cage, you’d fold it in half before putting it through. Here are the dimensions you can expect from this example.

Original Product Dimensions: 60 in x 80 in x 3 in (1524 mm x 2032 mm x 76 mm)

Final Package Dimensions: 8 in diameter, 40 in long (203 mm, 1016 mm)

Foam Pillow

Small products like this pillow can also be rolled in this roll cage. Here’s an example package for an all-foam pillow.

Original Product Dimensions: 22 in x 16 in x 4 in (559 mm x 406 mm x 102 mm)

Final Package Dimensions: 6 in diameter, 22 in long (152 mm, 559 mm)

Roll Packaging Features

Uses Only Stretch Film

Each product passes through a curtain of stretch film, which follows the product into the cage to wrap as it rolls.

Compress & Roll

Because these machines skip flat packing, the roll cage compresses as it rolls each product.

Easy-to-Handle Packaging

Final product diameters range from 6-9 inches (152-229 mm), making them ideal for retail and e-commerce.

Frequently Asked Questions

This mid-size roll cage uses stretch film to lock in the package.

This machine can be run by one operator.