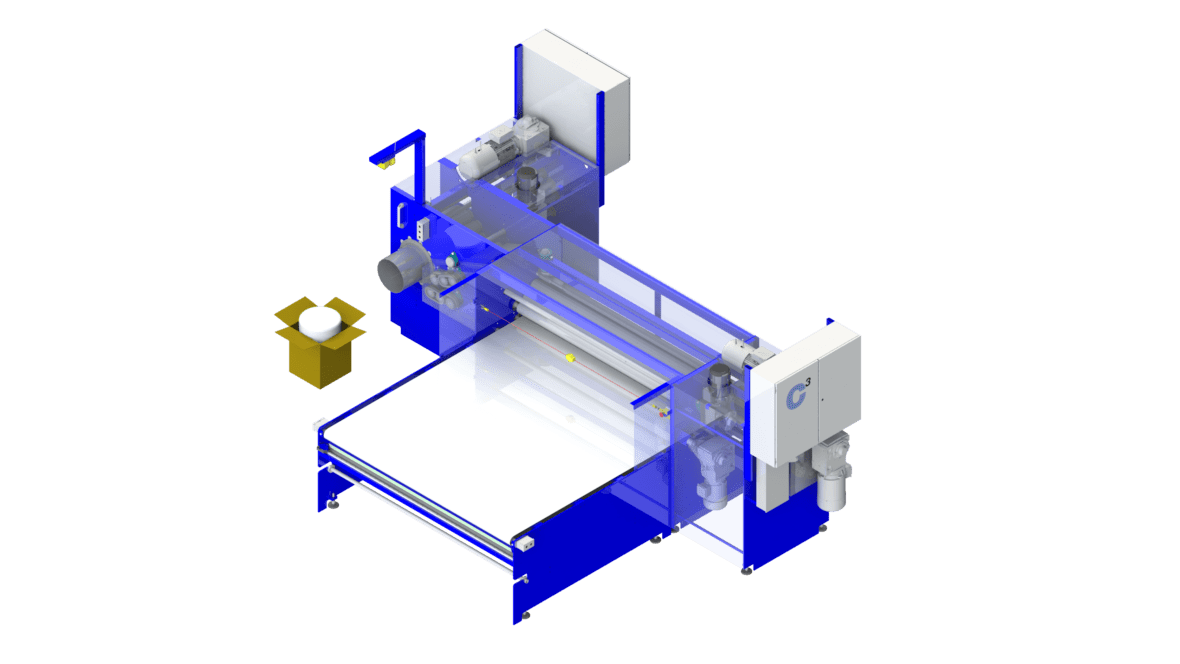

Product Overview

Compression Packaging Solutions For Foam Mattress Toppers, Layers, & Some Twin Mattresses

The mattress topper packaging machine packages foam sheets and toppers without the use of film. The machine consists of two roll cages that first roll the product to length and then roll it a second time to final package dimensions. The packages created by this machine return great shipping and handling savings, especially with major e-commerce companies and carriers.

Shelf-Ready Packaging For Foam Toppers

Our product-first methodology led us to the engineering of this machine. Manufacturers needed a way to quickly package foam topper products without clogging up their main production line.

This machine fulfills this need by creating packages for topper products perfect for store shelves and direct-to-consumer shipments. Foam toppers of all sizes work in this machine.

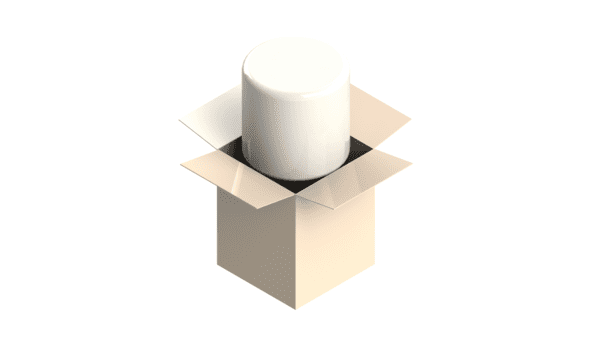

King Foam Topper

This king-sized foam topper is 3 inches in height with a 3 lb density. When packaged with the TC9513, it reaches the following dimensions.

Final Package Dimensions:

Diameter: 13.5 in (343 mm)

Height: 20 in (508 mm)

Mattress Topper Roll Cage Machine Features

Roll

Scrim material follows the product into the first roll cage as it is rolled to width.

Roll Again

The product is rolled a second time into its final package dimensions.

Easy Handling

As it exits the second roll cage, it slips into a sleeve that holds the compression. The final package is easy to handle.

Frequently Asked Questions

This system uses two packaging materials including scrim and sleeves. Scrim helps the product through the roll cages and the sleeve holds the final package in place. Both are low-cost options that replace film.

The topper packages typically fit into a 15 in x 15 in box, given an estimated diameter is 13.5 in.