Product Overview

Shorten Open Time Of Acrylic Glue

Acrylic glue's unique properties give it a longer open time than other glues. This means it takes longer to cure. The IR heating unit helps eliminate excess moisture and speed cure times so you maintain production without the need for additional storage space.

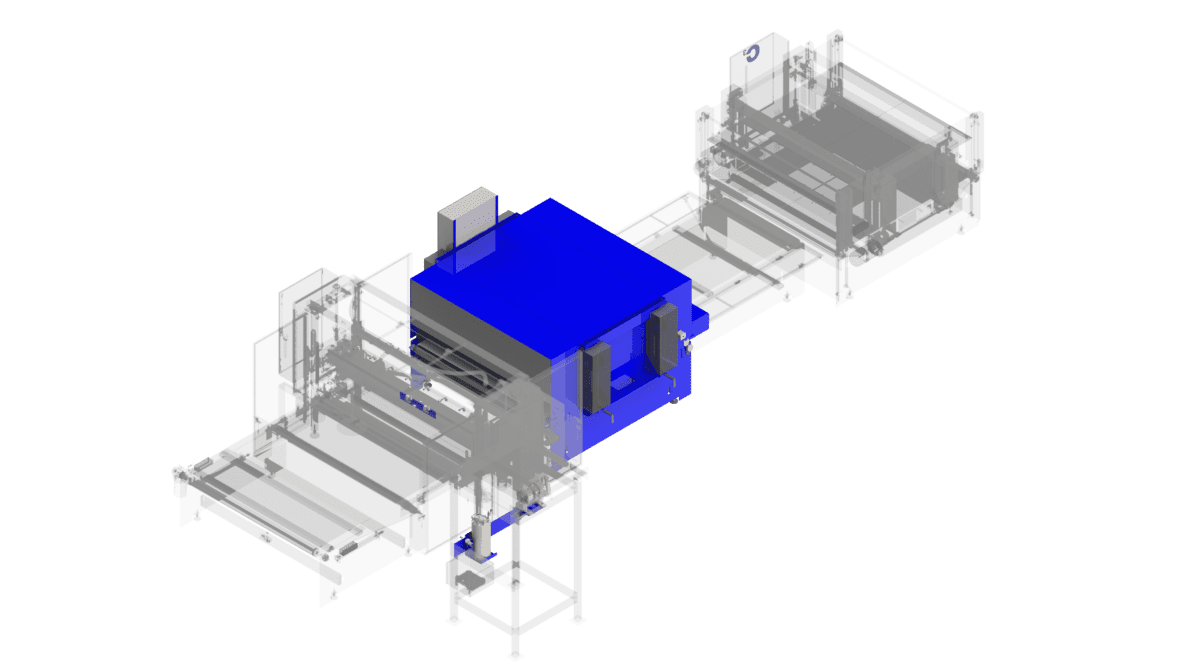

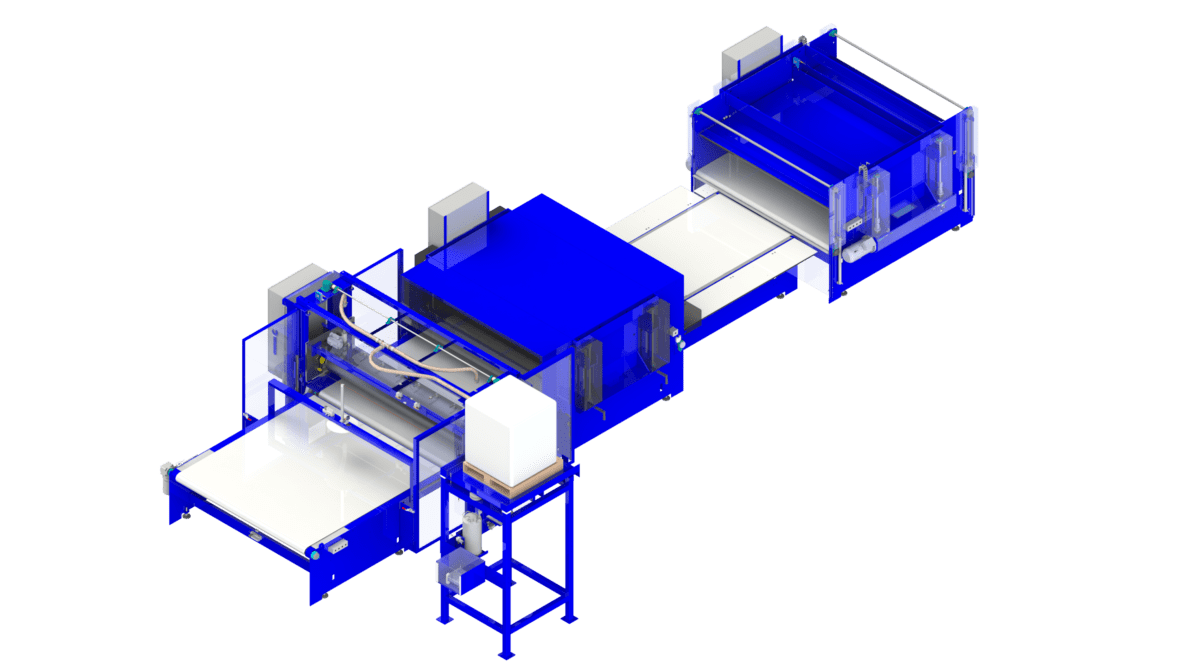

Where The IR Heater Fits In Lamination

The IR Heater is put in-line after the application rollers. Here, it aids in curing acrylic glue before layers are stacked to build a laminate.

Speeds Cure Time

Acrylic glue needs more time for curing. When you use an IR heater after the glue is applied to a layer cure time is reduced.

Reduces Need For Storage

When acrylic glue cures faster, that's less time you need in storage for curing.

Do More With Lamination

The IR heater is added to lamination systems when facilities wish to use acrylic glue in production and maintain throughput.

Wish To Add The IR Heater To Your Lamination Line?

Frequently Asked Questions

Acrylic glue takes awhile to cure. The IR heater speeds the cure time so you can move to assembly faster with less need for storage. Most facilities opt for an IR heater for this reason.

No, IR heaters are used when you wish to speed production with acrylic glue. Hot melt glue has separate add-on options.