Product Overview

Reduce Floor Space Needed to Unwind Coil Bales

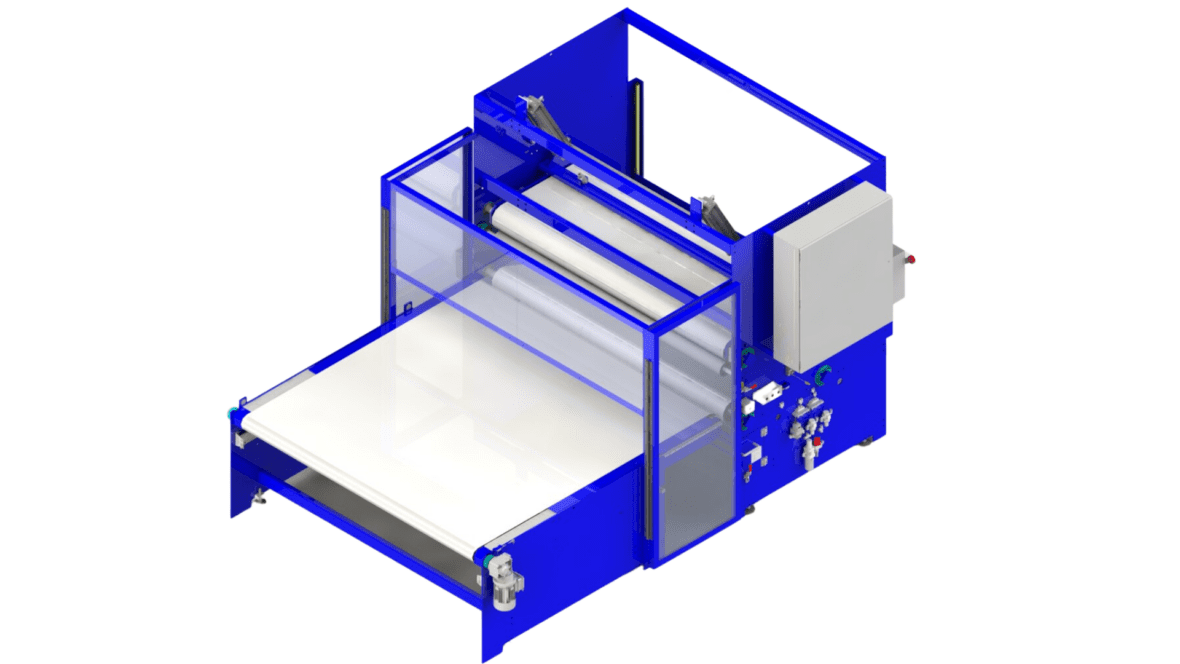

Manufacturers install the coil unbaler in their facility when they are looking to automate and reduce amount of floor space needed to unbale coil packages. A dual conveyor design provides constant compression on the coils which allows them to be unrolled in a safe controlled manner.

Material Handling Systems For Mattress Manufacturing

C³’s material handling machinery helps facilities keep track of work in process, take labor out of heavy lifting and material handling, and make efficient use of space in your building.

When conveyors, lifts, turn tables, flippers, and pushers take over the work of moving product, facilities run efficient production lines with more organization, product tracking, and improved safety for employees.

More Variability In The Same Machine

When C³ sets out to engineer a machine, we work to create a standard design that delivers the most-used functionality first. Then, we offer additional components that help you scale your equipment to suit your needs. These add ons are modular and can be added at any time to your line.

Frequently Asked Questions

Most pocketed coils and open coils work best when unrolling with the Unbaler. Every product is different – the best way to know is to contact C³ and schedule product to be sent to our facility for testing.

The Unbaler senses when a bale is complete and automatically stops the conveyors. It will retract the nip conveyor and lower the loading pan without any operator intervention. This minimizes downtime to load the next bale.