Product Overview

Store Products In A Trackable, Organized Manner

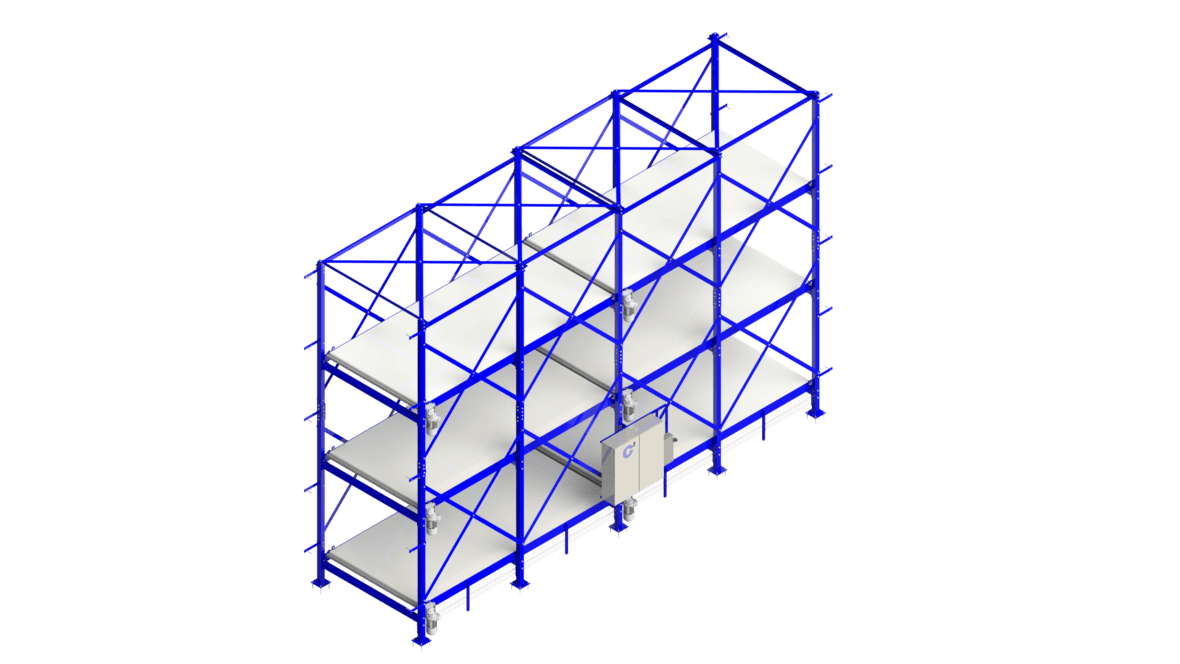

C³ storage systems are highly-customizable racks, lifts, and conveyors that work together to keep track of your inventory while it's curing or not in use. By taking advantage of the vertical footprint of your facility, it takes up less space than leaving stacked material on ground level.

How The Laminate Storage System Works

Entry

Product enters the storage system for curing, storage, or accumulation reasons.

Storage

The storage system's database tracks the time product sits in storage. For example, if a laminate needs to cure for four hours.

Exit

Product is picked and shuttled out of the system to the next stage of production.

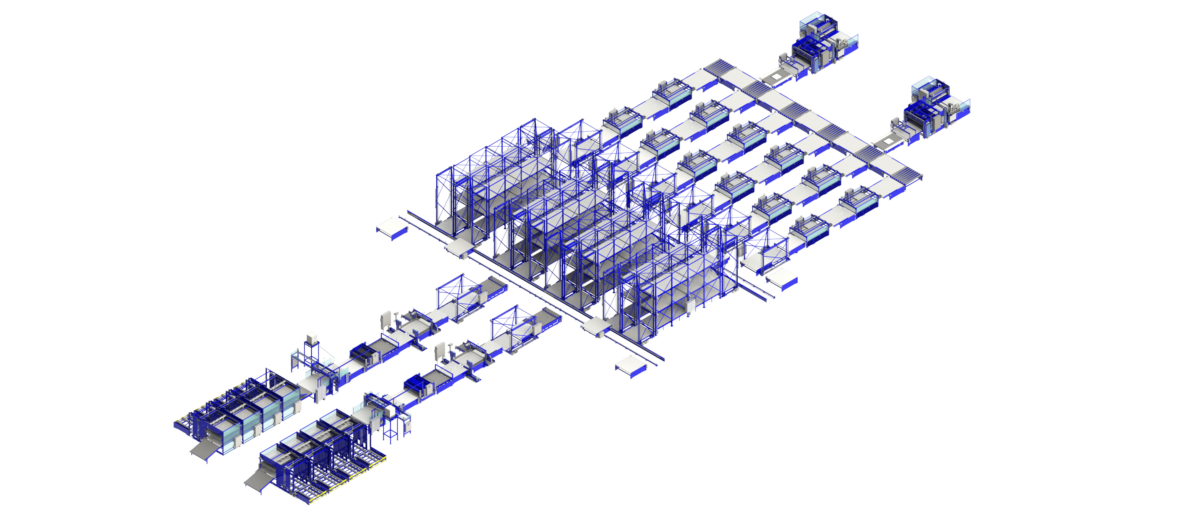

Where Storage Fits In Production

Obviously storage units are used for curing or storing product, but did you consider using them for accumulation? When you scale with automation, you may be able to take advantage of accumulating product before it passes to another section of production to take advantage of full throughput. Here's an example of a line where storage units are used for accumulation before assembly and packaging.

Optimize Your Operators' Time

Using a storage system to accumulate product from lamination allows the assembly team to make the most of their shift.

Never Lose Product

Storage systems keep products in production so they're traceable, rather than using a fork lift to store them around your facility.

Rapid Throughput

Robust automated lines like this one can produce one bed every 22 seconds.

Ready To Automate Your Facility?

Frequently Asked Questions

- Foam or latex blocks

- Stacked layers or pocket coils

- Stacked, finished mattresses

- Laminated cores