Product Overview

Leave The Lifting To The Machine

Stacking product is necessary at many points in a production line. You may want to kit product at the start of production or stack laminates for storage. Perhaps it's finished beds from assembly that you want to stack on a pallet. Wherever stacking is necessary, it can be automated with automatic stacking units.

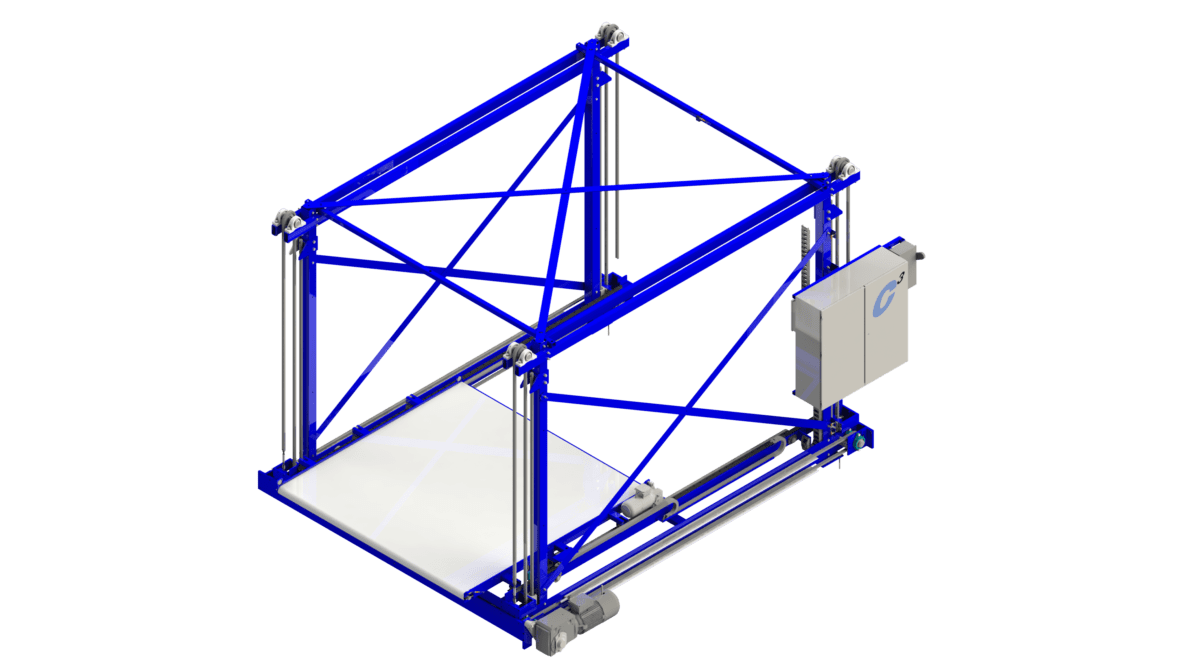

How The Stacking Unit Works

Lift

Products are lifted by the shuttle conveyor and moved to meet the stack height.

Stack

Product gently conveys off the shuttle to form an aligned stack.

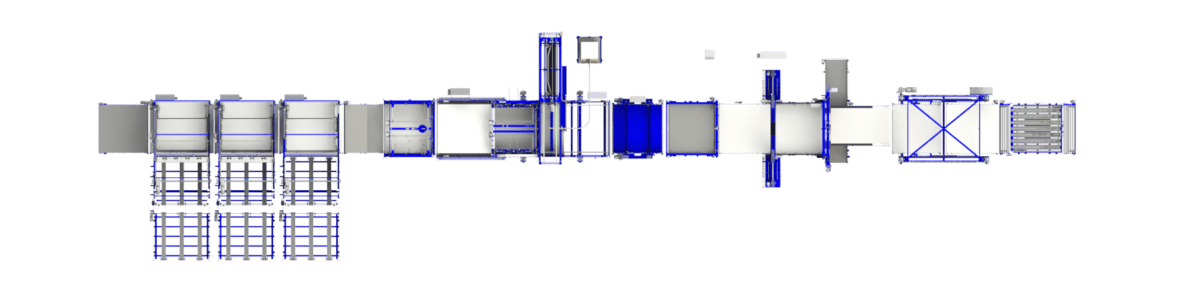

Where The Automatic Stacking System Works In Production

Automatic stacking units fit into production anywhere you need to stack product for moving through the facility or palletize it for shipment. See it in this example line.

Make Better Use Of Space

Stacking product can reduce how much space it takes up in a line. Instead of moving product unit by unit, you can move one stack of it.

Keep Product In Production

Automatic stacking units keep product in production so its trackable and not lost or damaged elsewhere.

Accumulate Product

Gather laminates for assembly or palletize finished beds for packaging to make the most of each section's production capacity.

Ready To Scale With Automation?

Frequently Asked Questions

Product can be stacked up to 60 inches high.