Product Overview

Put Covers And Fire Socks Onto Laminated Mattresses With Ease

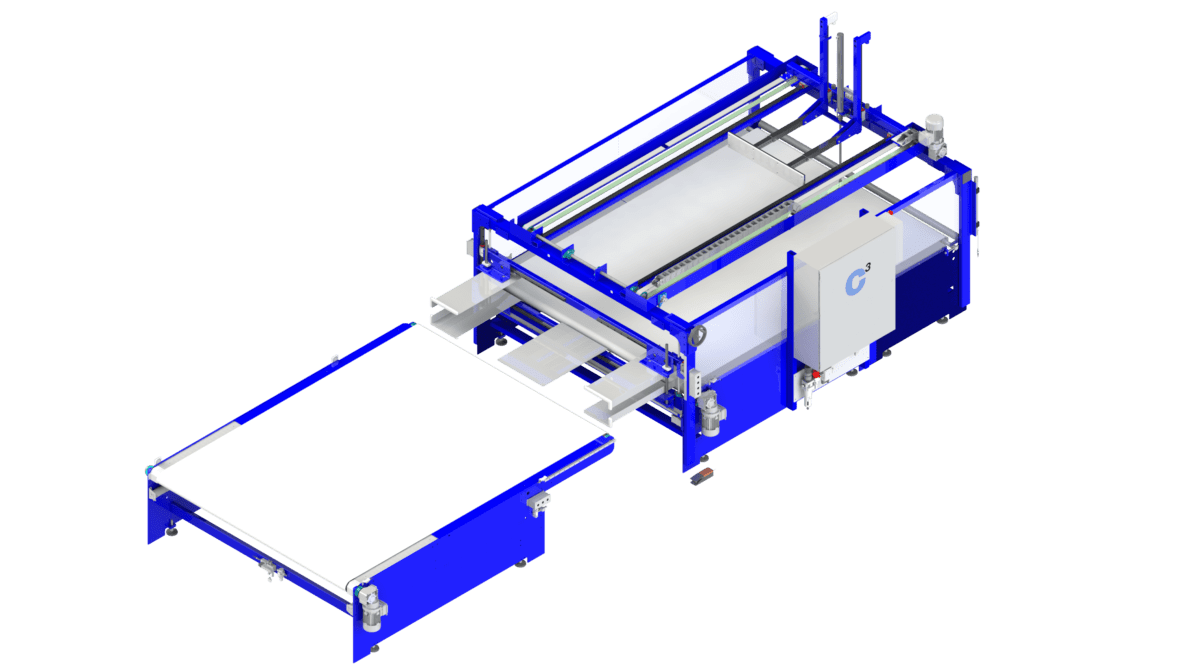

The pushing machine takes manual force out of assembly. By utilizing a pushing arm to gently guide product into a fire sock or cover, operators don't need to lift or move any heavy product. Four operators usually work at this section with two pushers, one station for the fire sock and the other for the cover.

Where The Pusher Fits In Production

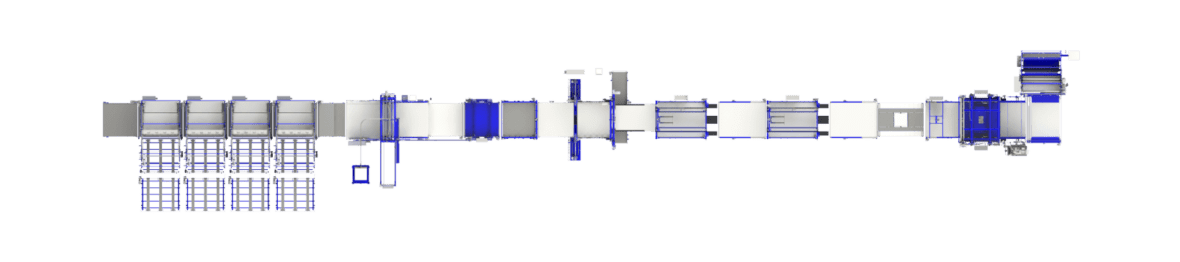

The pusher usually comes after lamination and trim is complete, when you have a finished laminate. In assembly, a facility might have two pushers, one for fire socks and one for covers, like you see in this example line.

Closer To Full Automation

Automating this process with the pusher system brings your facility closer to full automation.

No Heavy Lifting

Improve facility ergonomics by reducing the amount of lifting and keeping work within arms reach and at waist height.

Stay Consistent

Use the same machinery to add fire socks and covers in one unified assembly area.

Ready To Automate Your Assembly Line?

Frequently Asked Questions

The pusher can handle up to 250 lbs.

Yes! Most manufacturers use the pusher machine for an easier way to put on fire socks. With this, we add a sewing system from an outside vendor so operators can close the seam.

Yes! You tell us where you need to push something and we’ll show you how it could work with our push system.