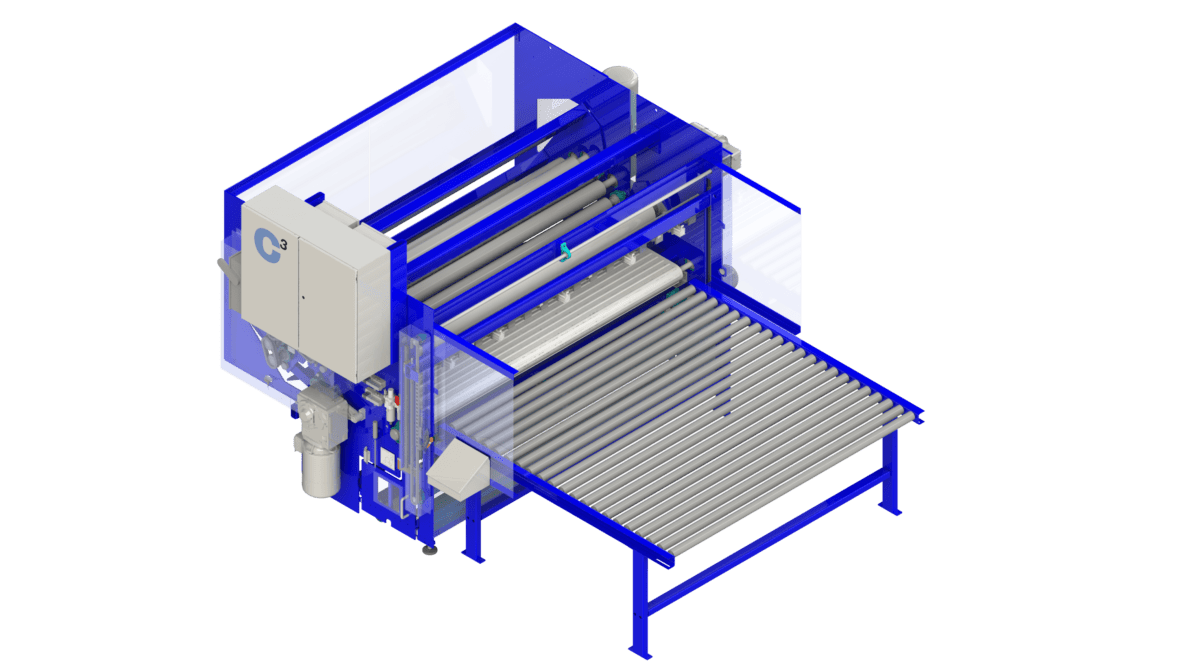

Product Overview

Cost-Effective Way To Roll-Package Large Foam Products

The RC9500 is an ideal entry-level mattress packaging machine for manufacturers that don't need a press and fold section. This design offers variety for packaging products from small wedges to toppers and inner-spring mattresses. Final package diameters range from 9.5-13.5 in. This machine is the smallest footprint available for packaging up to 90-inch wide products.

C³'s Package-First Methodology

C³’s package-first methodology led to the creation of this roll cage. Since some facilities don’t need a sophisticated packaging machine like our compress, fold, and roll system, we engineered this roll cage machine to suit mattress-sized products.

This machine is ideal for products of all foam and some pocket coil products. It takes advantage of compression packaging savings with a cost-effective machine. Here are examples of products packaged with this roll cage.

Full All-Foam Mattress

Mattresses can be packaged to width in this roll cage. Here’s an example when this bed is ran through the machine.

Original Product Dimensions: 75 in x 54 in x 10 in (1905 mm x 1372 mm x 254 mm)

Final Package Dimensions: 11.5 in diameter, 54 in long (292 mm, 1372 mm)

4-Inch Mattress Topper

Mattress toppers are easily rolled in this roll cage. Here’s an example with a 4-inch King topper.

Original Product Dimensions: 80 in x 76 in x 4 in (2032 mm x 1930 mm x 102 mm)

Final Package Dimensions: 10 in diameter, 40 in long (254 mm, 1016 mm)

Final diameter is product dependent and can range from 9.5-12 in.

Roll Packaging Features

Uses Only Stretch Film

Each product passes through a curtain of stretch film, which follows the product into the cage to wrap as it rolls.

Compress & Roll

Because these machines don't flat pack first, the roll cage compresses as it rolls each product.

Easy-to-Handle Packaging

Final package diameters range from 9.5-13.5 in (241-343 mm), and are easily boxed with the help of a boxline add-on.

Frequently Asked Questions

The diameter of the package is product-dependent, but the machine produces diameters from 9.5 inches to 13.5 inches. The width of the package is based on the width of the product.

If you have smaller production numbers, all-foam mattresses, or are looking to get started in packaging, this roll cage is a less-expensive way to reap the benefits of compression packaging. It also is effective if you package more than just mattresses in your facility.

If you want to fold your products for a traditional bed-in-a-box package, then you’ll need to consider the compression folding machine instead.

This machine uses only stretch film for packaging.