Product Overview

Compression Packaging Solutions For Foam Mattress Toppers, Covered Toppers, Plates & Small Beds

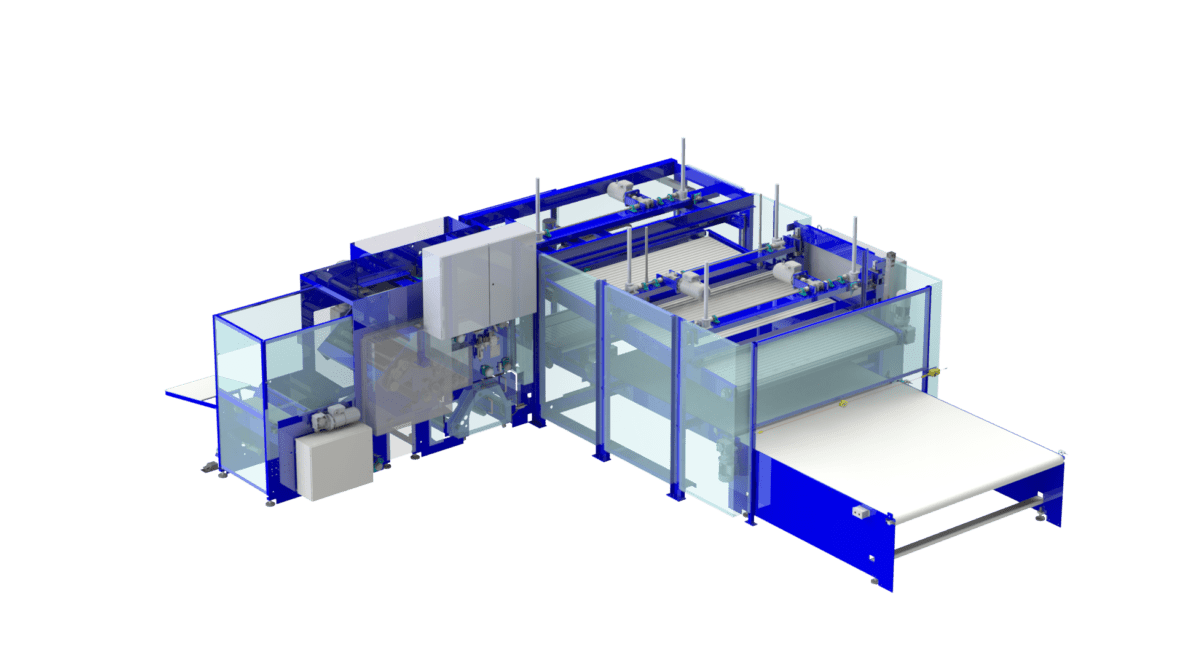

The mattress topper packaging machine packages foam plates and toppers with one consumable (paper or stretch wrap). The machine consists of two roll cages that first roll the product to length and then roll it a second time to final package dimensions. With our fully automatic design, no prior hand rolling needed. The packages created by this machine return great shipping and handling savings.

Shelf-Ready Packaging For Foam Toppers

Our product-first methodology led us to the engineering of this machine. Manufacturers needed a way to quickly package foam topper products without clogging up their main production line.

This machine fulfills this need by creating packages for topper products perfect for store shelves and direct-to-consumer shipments. Foam toppers of all sizes work in this machine.

Topper Compression Machine Features

Conveyor

Adjustable nip conveyor rolls covered and uncovered toppers with full control.

First Roll

The product is rolled and held while on the transfer station.

Easy Handling

Secondary roll cage adjust and wraps product to final size. Boxline allows for easy removal and placement in box.

Frequently Asked Questions

This system uses only one packaging material, paper or stretch wrap. No Scrim needed. Lower cost per package are low-cost options that replace film.

The topper packages typically fit into a 15 inch cube box. Send us your product specifications today to determine what package sizes are possible.