Product Overview

Turn Product Without Manual Labor Or Disrupting Production

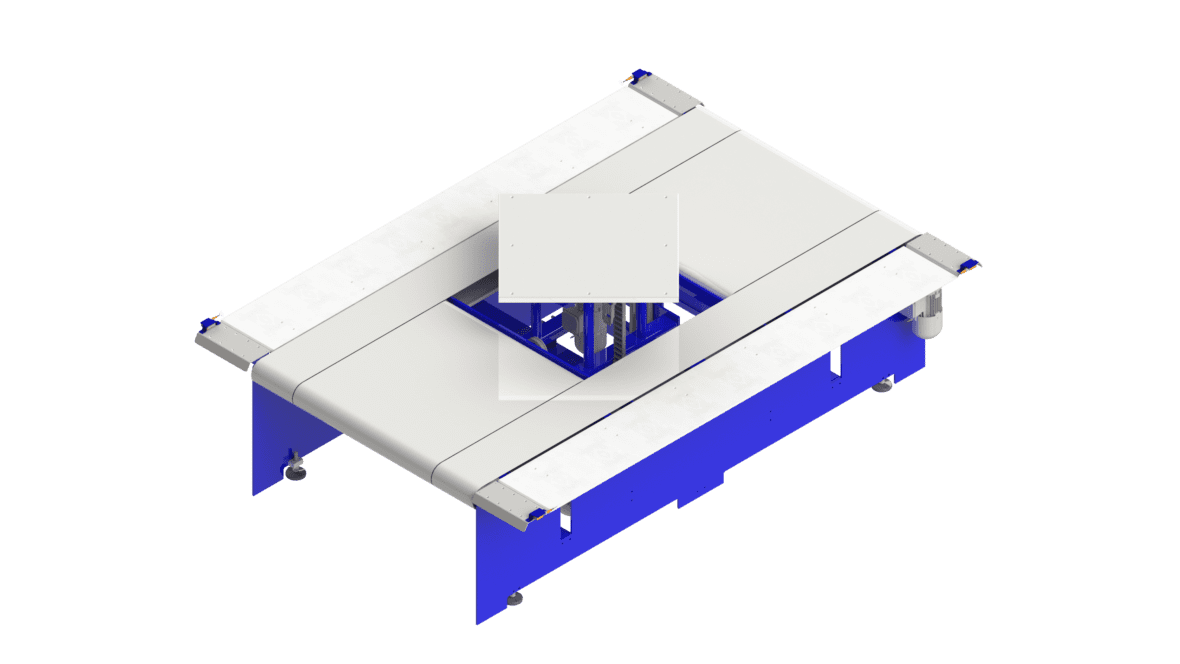

The turn system is your ergonomic solution to rotating product without the exertion of an operator. The machine lifts the product and rotates it to the degree needed to continue on to production. Most manufacturers use the turn to perform activities like zipping covers, final inspection, or removing debris.

Where The Turn Table Fits In Production

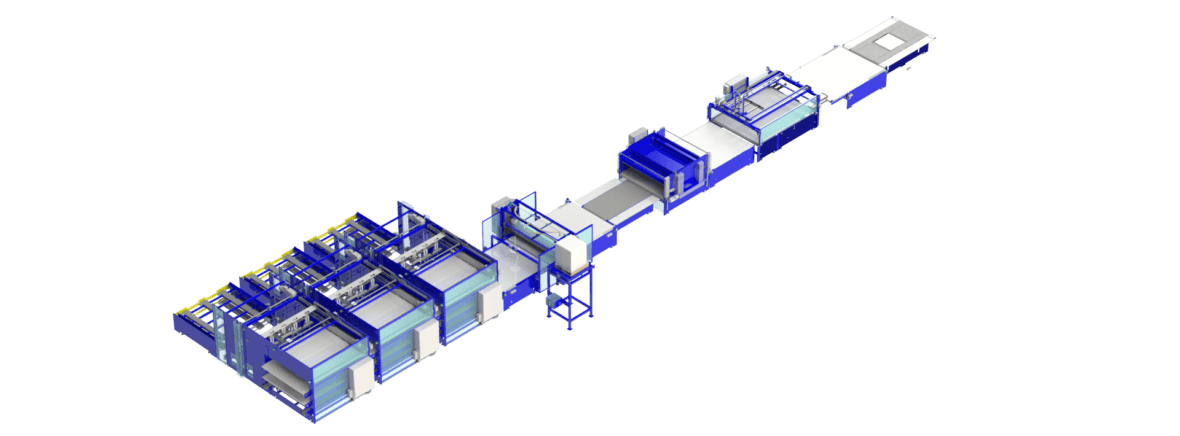

The turn table fits into production in many different areas depending on your operation. Here is an example of how it could fit into a full production line.

360-Degree Product View

When a product is lifted, an operator can see all sides of the product to ensure it's clean and ready for packaging.

No Heavy Lifting

Flipping, turning, or moving around laminates or mattresses is heavy and awkward for operators. This turn table improves ergonomics and keeps everything at waist-height.

Final Product Check

When the turn table is used right before packaging, it serves as a final inspection point for operators to make sure the product is perfect for your customers.

Ready To Automate Your Production?

Frequently Asked Questions

Max product dimensions are 84 in x 84 in x 18 in (2134 mm x 2134 mm x 457 mm).

The turn table can lift product up to 400 lbs.

Infinite! You’re sure to be dizzy before this turn table stops turning.