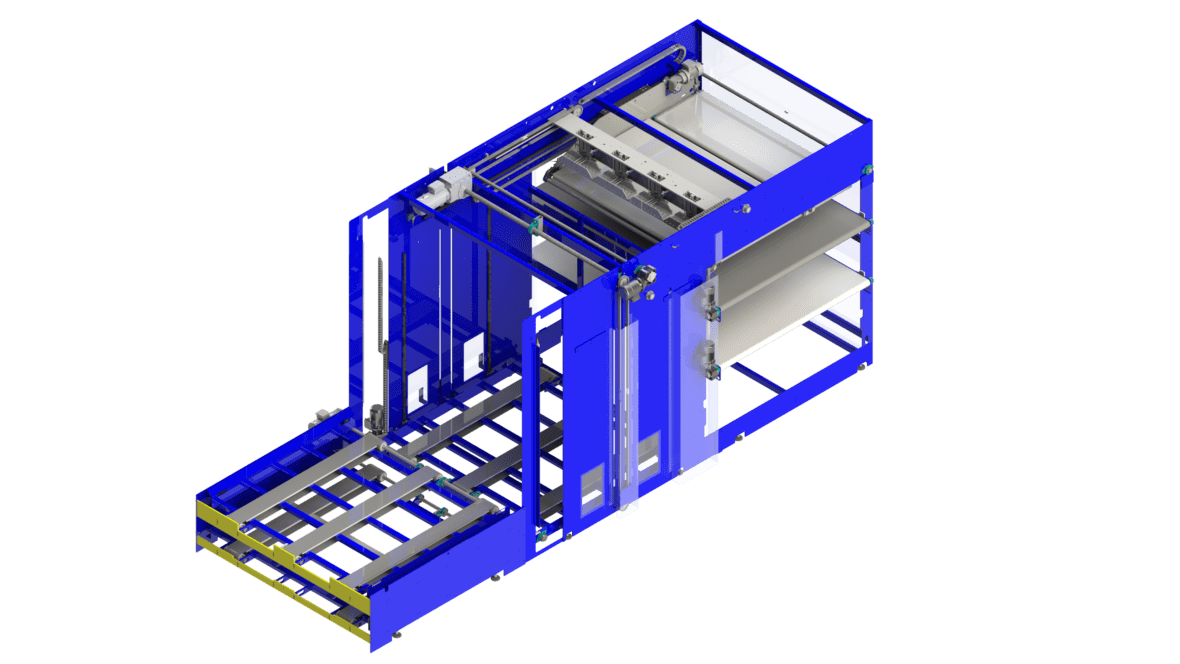

Product Overview

Pick Foam Layers From A Stacked Pallet And Convey Them Into Production

Destacking units are typically used at the start of a lamination line to unload pallets of foam, latex, or pocket coils. Each layer is conveyed to a lamination system in order of the laminate build to automate the raw material infeed. Empty pallets are then recycled automatically through the machine for pickup by a forklift.

How The Destacking Units Work

Pick

Using a bump conveyor or pickheads, product is picked and conveyed into the production line.

Convey

Product conveys in order of a recipe into the lamination system. Multiple destackers suit the number of layers in a mattress build.

Recycle

Empty pallets are shuttled through the machine and return to the same place they started for pick up.

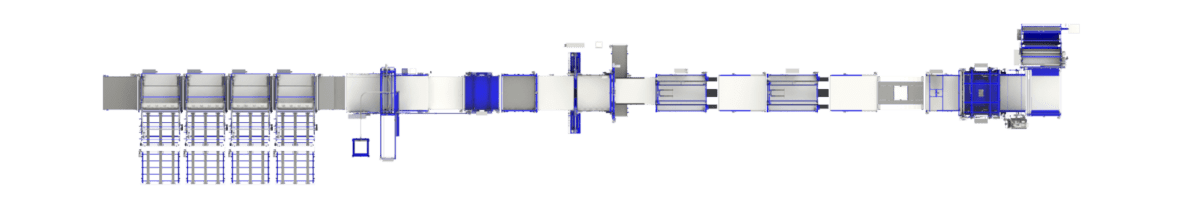

How The Destackers Fit Into Production

Destacking units automate the start of your production line by feeding raw material. Here is an example of where these units fit in an automated line for a four or five layer build.

Improved Material Handling

Destackers at the front of the line keep forklift traffic organized with the same drop off and pick up locations.

Consistent Product Infeed

Raw materials are fed into production by order of recipe and kept square as they pass to lamination.

Scalable Units

Opt for the number of destackers that best suits your production with the option to feed special material through the back side of the destacker.

Ready To Scale Your Lamination Line?

Frequently Asked Questions

There are two destacking unit models that can handle 58 inch stacks or 80 inch stacks.

The destacking unit can pick layers from 1/2 inch thick to 8 inches thick.