ISPA Expo is right around the corner, this year in the vibrant New Orleans! We’ll be onsite at Booth 100 with a full production line featuring our newest lamination machine, the LCN1250 model, that brings incredible speed and ergonomic improvements to mattress manufacturers. This is one demo you can’t miss!

We’ve been busy prepping at our Wisconsin facility, and our Business Development Leader, Mark, wanted to take a minute to fill you in from our production floor. Click play to hear Mark’s take on the most exciting features of what we’re bringing to the show.

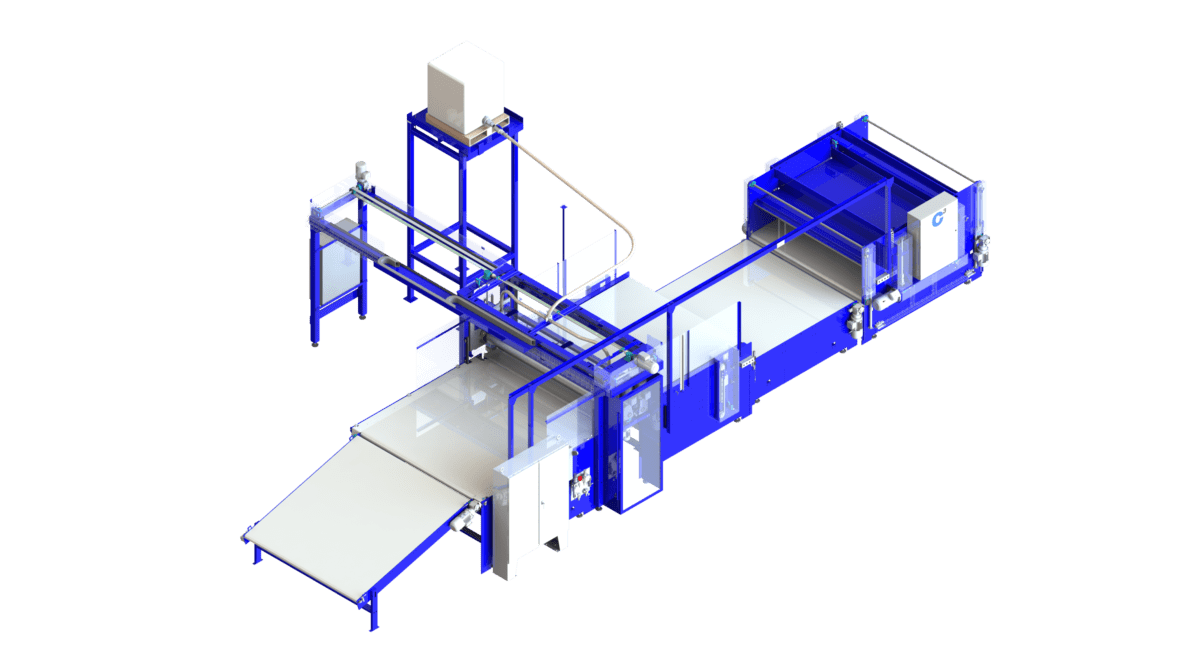

Debut of the New LCN1250

How many beds per minute does your lamination line produce? What’s your rate of overuse injuries or turnover for lamination operators?

C3’s newest lamination machine, the LCN1250, debuted to the market this year as the fastest, most ergonomic-friendly lamination system available. With incredible speed enhancements, the machine has a throughput of 200 feet per minute, which equates to 10-12 plates or 2-3 beds per minute. With advancements like automatic gap control, new functionality like the merge table, and the recommended use of synthetic latex glue, lamination will no longer be a bottleneck to your manufacturing.

This method for achieving high throughput is not at your operators’ expense – it actually makes their jobs easier. Watching typical production, our engineers noticed a lot of heavy lifting through awkward ranges of motion. This new solution includes a pivoting conveyor over the laminate, which accurately merges each freshly glued plate with the rest of the build. Operators now only need to make simple, waist-high adjustments to perfect the placement – no more heavy lifting of sticky layers or time-consuming manual stacking.

Smart Packaging Innovation

You’ve likely seen our compression packaging machine before, but have you seen the new smart package features? The “smart package” is what we call the product that exits our compression folding system when it’s equipped with our new variable roll cage and updated HMI software.

We use our compression roll cage calculator to determine the potential package dimensions for a product. What used to be just a stand-alone tool is now built directly into the HMI software so it’s completely integrated into the packaging process.

With the use of the tool, the machine uses measuring devices to take the dimensions and weight of the incoming mattress. Then, it monitors the density and volume changes as it compresses. Using this data, the machine can determine what to set the roll cage to for optimal product recovery. This technology significantly reduces the reliance on operators to remember product recipe information and reduces the number of inputs needed per shift, meaning an easier and less-demanding workload.

Full Production Live

Shows like ISPA Expo are a great place to see and compare machinery, but have you ever seen a full manufacturing line on the show floor?

We’re going to make beds!

Our new lamination machine will feed into an assembly station and then move straight into packaging. Within minutes, you’ll witness a bed be made before your eyes. “Ooo’s” and “Aah’s” are optional, but we encourage you to open up the package and see how the bond adhered and the product recovers.

Our line showcases our lamination and compression innovations of the past twelve months. You’ll see incredible improvements in throughput and ergonomics on the lamination system and new automation technology advancements on the compression system. You’ll see how the technology unites to build beds with more efficient use of resources including glue, labor, and time.

This is a showcase you won’t want to miss. Visit our booth daily for live demos, sign up for reminders and we’ll see you at the show!