Hot melt is the preferred bond in hybrid mattress production, but the process can be challenging. We asked ourselves, “How can we simplify this process while increasing speed and efficiency on the floor?” By reimagining hot melt, we developed an advanced hot melt bridge unit that will change the future of hybrid mattress production.

Build Quickly

Goals, deadlines and consumer demands can sneak up before you know it. Stay on top of hybrid mattress production like never before with this hot melt bridge unit.

The hot melt bridge unit has a belt speed rate of 200 feet per minute. That’s about five to six times faster than the average machine! This means a complete hybrid mattress can be built as quick as 21 seconds, with each layer taking 6–10 seconds to glue.

Just imagine how much faster you’ll be able to meet consumer demands with that kind of speed. That’s the power of bigger thinking.

Move Efficiently

By creating the hot melt bridge unit to be a part of the LCN1250 lamination machine, a single hybrid mattress can be built all on one machine using the edge-to-edge coil style, foam-encased coil style or any style you prefer. Because the bridge is modular, it can be set up to best accommodate your specific build spec.

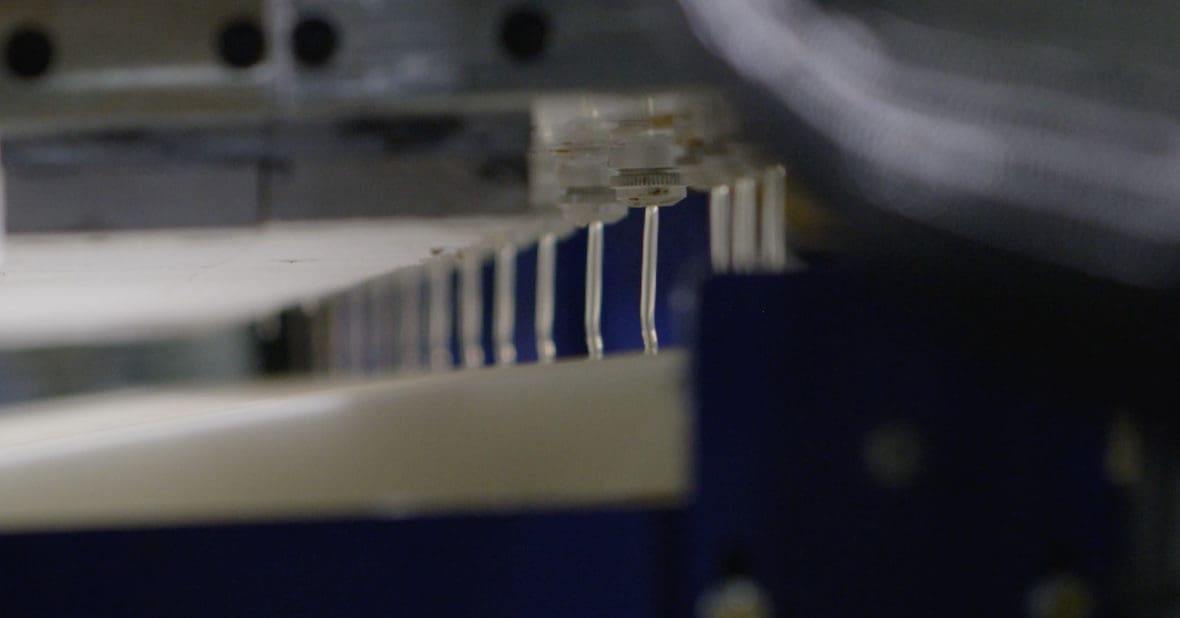

On top of that, we’ve also streamlined the set up. Just one hose from the hopper to the bridge can feed up to 30 spray heads, unlike most hot melt bridge units that need one hose to one spray head. Adjustable heat zones in the hopper help to filter the hot melt and prevent charring. Both features minimize the amount of equipment used and reduce the time spent cleaning hoses. Less charring and less maintenance are huge benefits to keeping production moving.

Just imagine how much more efficient you’ll be able to move on the floor. That’s the power of better ideas.

The future of hybrid mattress production is here. Don’t miss out and fall behind. Contact your sales rep or reach out to us for more details.