Clearly, the bedding industry isn’t asleep, and it was thrilling to engage in so many eye-opening conversations at this year’s ISPA Expo in Orlando, FL. As the largest sleep products tradeshow in the world, the ISPA Expo is the best place to showcase innovations and connect with attendees.

Hot melt became a hot topic throughout the ISPA Expo. From speed to control to cleaning, it’s impressive to see the advancements being made, and we appreciate how many attendees immersed themselves in our head-turning ideas.

“We have shifted from being known for the roll coat to now having flexibility where the hot melt can be integrated with our existing machinery,” Business Development Executive Mark DesJardin said.

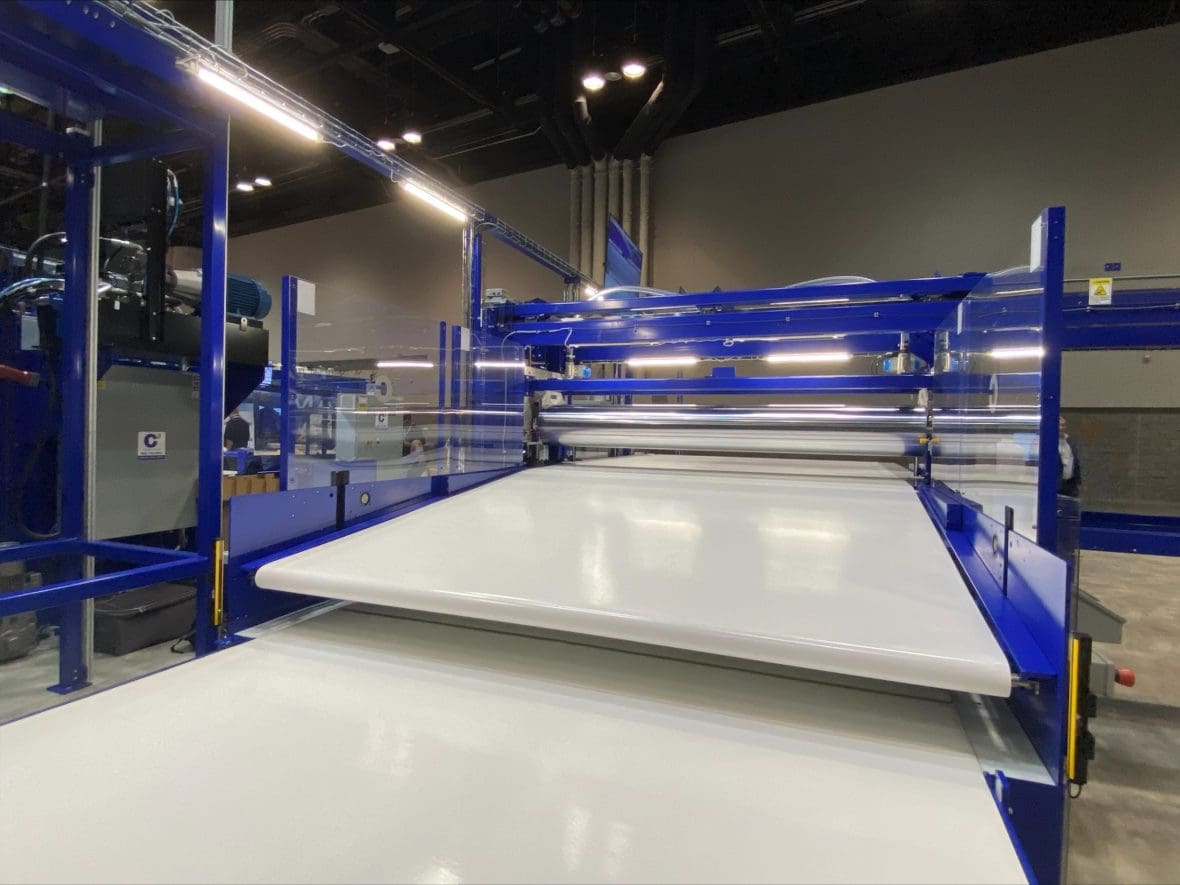

At a belt speed of 200 feet per minute paired with a pump to disperse 4 gallons of hot melt per minute, attendees were inspired by the speed and control of this hot melt bridge design. The discussion quickly moved to how many beds per shift could be completed.

“Our C3 patent pending comb tip technology on the bridge fascinated attendees as well,” DesJardin said. “We know hot melt can be challenging, so we created the comb tips to push the bead through for easy and safe application.”

Let’s not forget about the hot melt solution, which was another big hit at the ISPA Expo. “Clients have confirmed our application is extremely powerful for new markets,” VP of Sales Josh Vande Hey said.

From an environmental perspective, paper wrap generated many discussions throughout the ISPA Expo. Sustainability and recyclability are becoming increasingly important when it comes to packaging, and attendees were impressed with the benefits of paper wrap.

There’s also the potential of marketing on the package itself. We’re currently working on ways to display logos and other print on the paper wrap, allowing another marketing placement for your brand during the unboxing process.

Lastly, as outside forces have challenged the working environment, we’re seeing a pattern in moving towards automation and increased throughput — how to produce more with less people.

The CF1396 compression machine automates the packaging process, and the trifold add-on shrinks the end size smaller than the average bed-in-a-box. For lamination, the LCN1250 machine efficiently handles glue application and automates the lifting and placing of the mattress layers. Hot melt can easily be controlled with the roll coat to ensure the right amount of glue is applied.

Attendees observed throughput first-hand at the ISPA Expo with these machines, inspiring a different way of thinking about production.

“Whenever we get to be around people, it gives us the opportunity to build trust. And when trust is present, it can be embraced for better ideas and bigger thinking,” DesJardin said.

And that’s a wrap (pun intended) on the 2022 ISPA Expo! Reach out to see what’s new and begin moving forward.