A number of mattress manufacturers are increasing their resources to suit e-commerce based bed-in-a-box packaging. If you are looking to expand your direct-to-consumer shipment offerings, you may experience a number of changes attached to the transition.

Shifting to e-commerce for compression packaging doesn’t have to be daunting or difficult, especially when adopting the right automation solutions. The upgrades we’ve developed for our CF1396 Compression Machine and Variable Roll Cage make it simple to use and act as a QC check for every product. By combining our existing compression tools with measuring devices right into the machine, you’ll be confident that each product is packaged safely.

See how the CF1396 monitors the product with its smart features so you’ll always be sure of what you are shipping out to customers.

What Smart Compression Technology Means For You

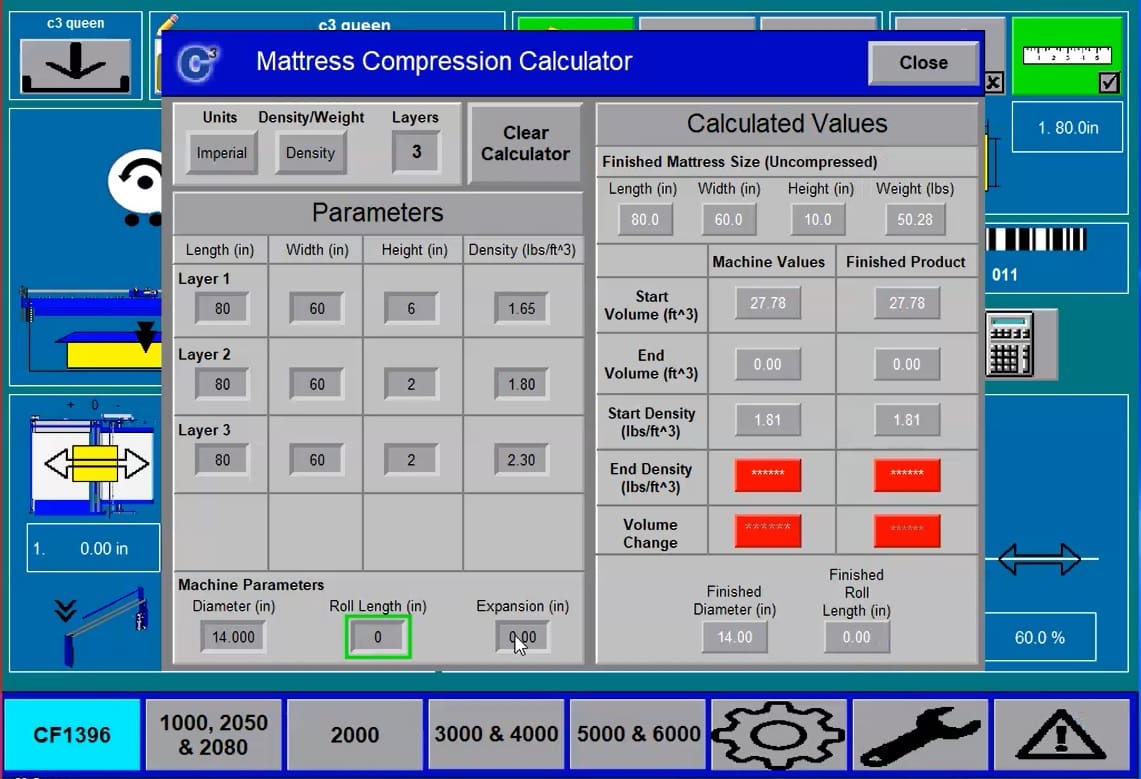

C3 engineers developed a compression calculator based on thousands of tests on a variety of beds and foams. Previously, we’ve used this tool to determine safe compression limits for each product before ever running it through a machine. Now, we’ve added this tool to the HMI so operators have it right in front of them on the machine. With this integration, it checks each bed in real-time to verify it is meeting recipe expectations.

This allows operators to run the machine with confidence that no products are over-compressed or risk damaging the machine. Plus, you’ll ship to customers with confidence that the product they ordered is what they’ll receive.

Simplified Responsibilities For Your Machine Operators

When making a rapid shift in production processes, training your staff on a new piece of equipment feels like a time-consuming barrier. The CF1396 with Variable Cage is easy to use and offers an added layer of protection for your products. We did this by taking the tools our engineers use to determine the viability of compression packaging for a given product, adding additional measuring devices, and incorporating them right into the machine.

The first thing we added is the compression calculator to the HMI. This way, when you enter a new recipe into the machine, you can double-check that the mattress will fit in the desired roll diameter from the recipe screen. This is a slimmed-down version of the same calculator our team uses when helping you determine which of your products can be safely compression packaged and to what degree. It’s a great way to double-check your specs against your recipe before you begin a production run.

Next, we integrated measuring devices at the infeed so the compression calculator runs in real-time. For every bed that passes the infeed, the machine measures its weight and dimensions. Combined with the press’s volume and density change readings during compression, this results in a real-time roll cage calculation. If the machine determines a product will not safely fit in the recipe’s roll cage setting, it will alert the operators.

The addition of these smart measuring devices means operators focus more on monitoring data and notifications on the HMI, rather than memorizing recipes and specs. It eases their responsibility load, increases the consistency of your packaged products, and still maintains a packaging rate of 2+ products per minute.

Improved Product Consistency And Customer Satisfaction

Another daunting factor when pivoting into e-commerce is delivering on customer expectations. Fewer shoppers are interacting with your products on a showroom floor, and more are turning to online reviews when determining where to buy. By using a machine that monitors product quality against your recipes and our roll cage calculator, you’ll rest easy knowing your customers will receive products that will fully recover from compression and meet their expectations.

The purpose of the roll cage calculator is to avoid compression set, or permanently deformed foam caused by too much compression. By monitoring the compression data while it’s happening, the machine detects quality issues that operators would miss and result in compression set, such as incorrect raw materials. The smart features of our Variable Roll Cage system act as an added layer of defense against incorrect or overcompressed products leaving your facility, effectively reducing the rate of return due to foam that won’t recover.

Look in-depth at the CF1396 packaging possibilities in MACHINE, and learn how to better control product quality with a spec in SKILL. You can also request a quote, and our team will help you find the right packaging solution for your operations.