The mattress industry is surging right now, particularly when it comes to online bed sales. We’re hearing many manufacturers are over capacity, adding facilities, machinery, shifts, and other resources to keep up with the demand.

With all of the additional run-time, it’s almost guaranteeable that you’ll need to keep up on service and preventative maintenance more often than you have before. Even if you already hold to a strict maintenance schedule, you’ll need to up your game to maintain the pace you’re running the machine. The last thing that anyone wants is a machine to go down during a period of max production.

While you can’t prevent all maintenance issues, you can be prepared. Our engineers and parts gurus put together this list of the top 14 spare parts they recommend you have on hand at all times for a CF1396 Compression Machine. Of course, these parts are essential to the function of the machine, but they also make our list here because of:

- The quantity that are needed on the machine,

- The potential for long lead times, or

- The high cost of expediting these parts in times of emergency. We’ve seen enough horror stories of customers paying incredible expedited shipping rates they could have avoided by keeping the part on hand.

If the current high demands and pressures on production weren’t convincing enough, we’re now approaching the holiday season. Predictions forecast early holiday shopping, with much of it online. Experts even started calling the changing shopping habits “the end of Black Friday as we know it” due to the shift towards e-commerce.

Maintaining throughput on your packaging lines will be even more essential through this holiday season due to increased online sales that favor bed-in-a-box type products. Having the right parts on hand for this equipment will keep you from added delays or surcharges commonly faced during this time of year.

While these aren’t the only spares you should consider, these are the hot few we recommend you always keep stocked as we enter the busy season.

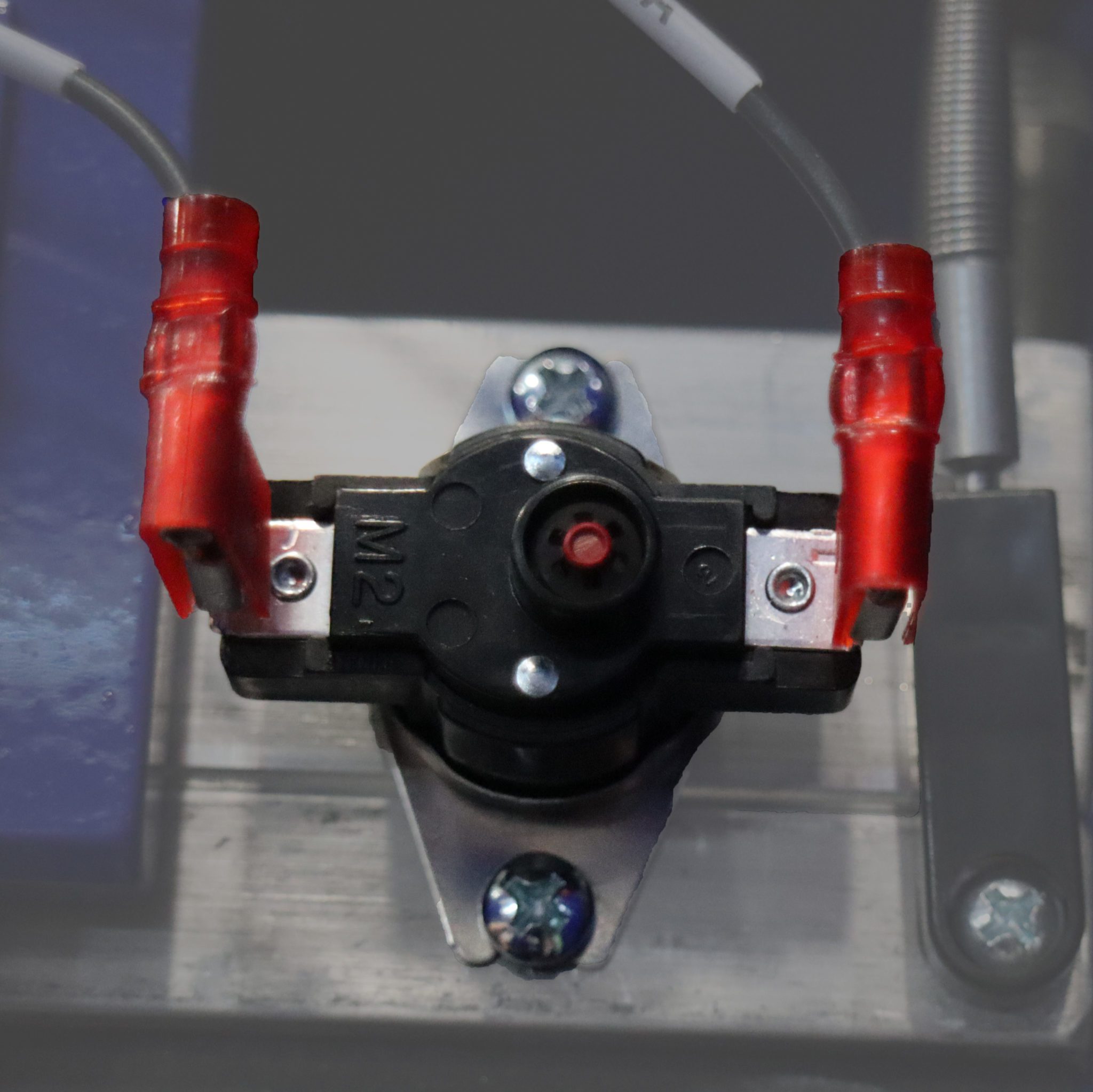

1. Thermostat, Notched 360 Degree

Part ID: 01-1700007

What It Does: The thermostat acts as a circuit breaker for each seal bar. If, for some reason, the seal bars were to overheat, the thermostat interrupts the circuit and cuts the power.

How Many On My Machine? 3 – one for each seal bar.

2. Thermocouple, 3FT Lead

Part ID: 02-1800433

What It Does: The thermocouple is what actually controls the temperature of each seal bar. It also sends the signal to the Watflow controller where you can see your temperature readout for each seal bar.

How Many On My Machine? 3 – one for each seal bar.

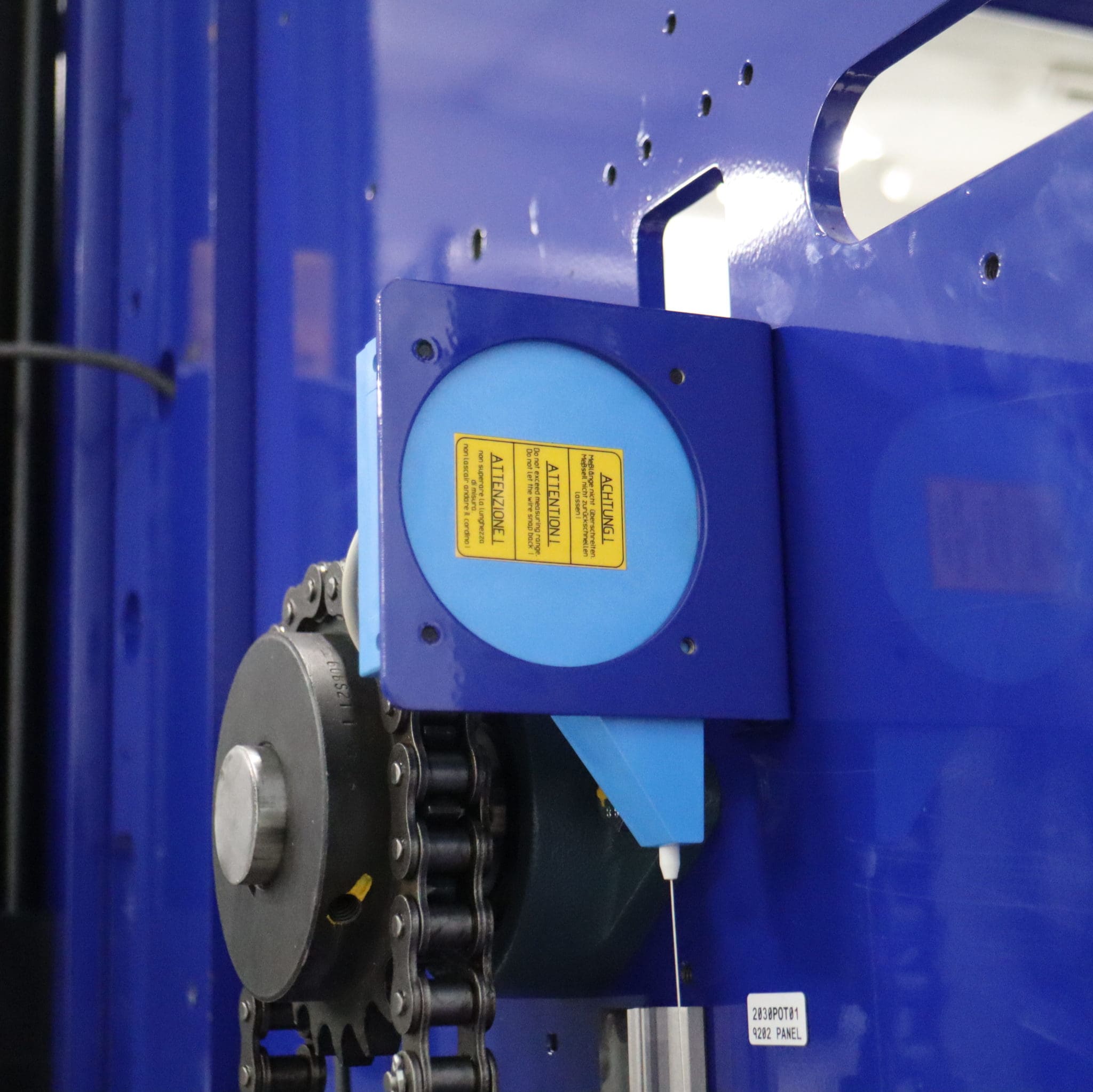

3. Encoder, Wire Draw

Part ID: 01-1900004

What It Does: These encoders (also called string pots) are used for reading linear travel. Ex: the encoder for the front seal bar tells the machine the height of that seal bar at any time. Any machine part that moves in a line – horizontal or vertical – has one of these encoders connected to it.

How Many On My Machine? Standard cage – 13; Variable cage – 16

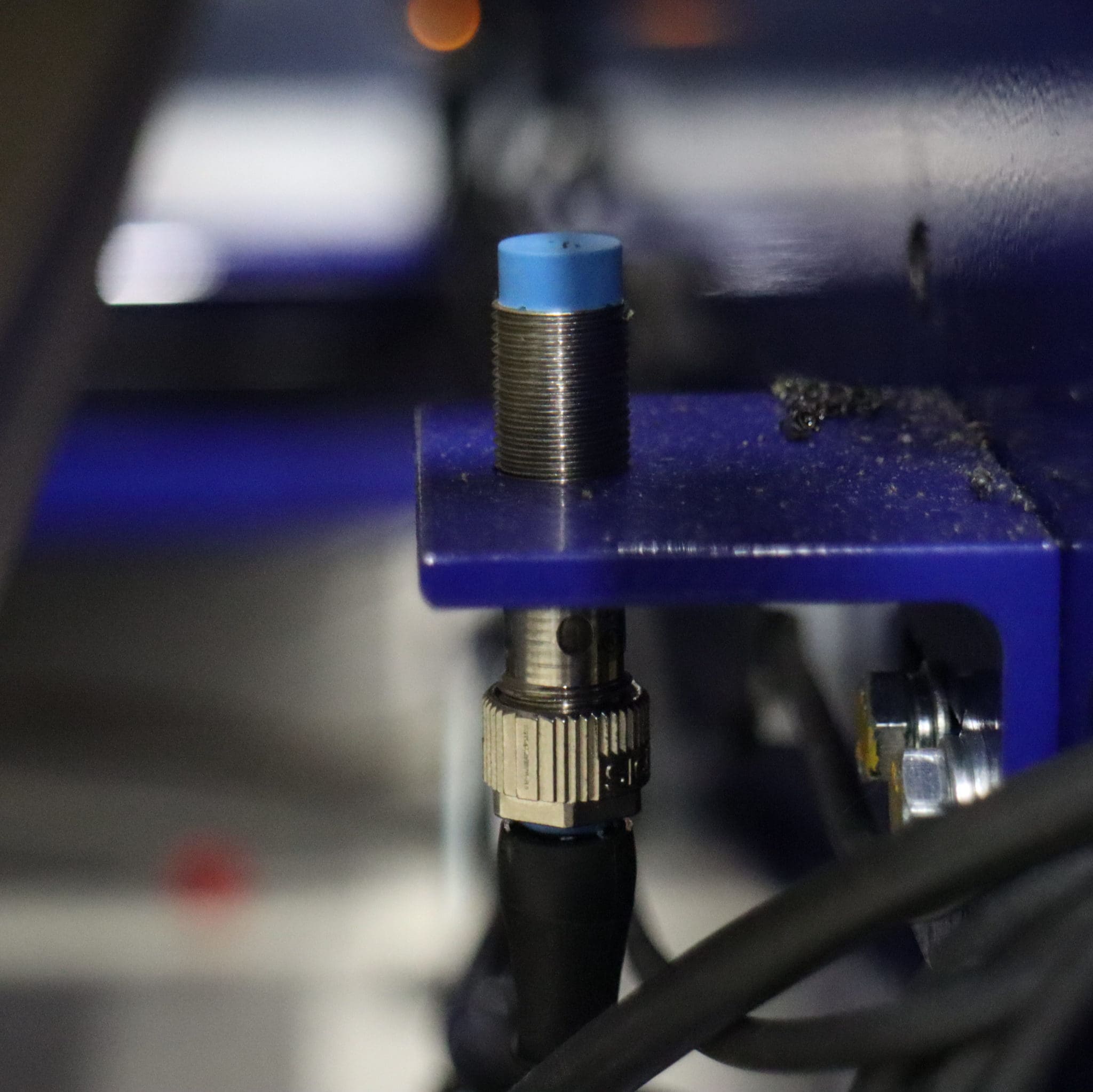

4. Sensor, Prox, No

Part ID: 01-1900022

What It Does: These sensors read the presence of steel and are commonly set to prevent overtravel. For example, once the prox sensor detects the presence of the exit pusher, it won’t travel any farther.

How Many On My Machine? Standard cage – 17; Variable cage – 23

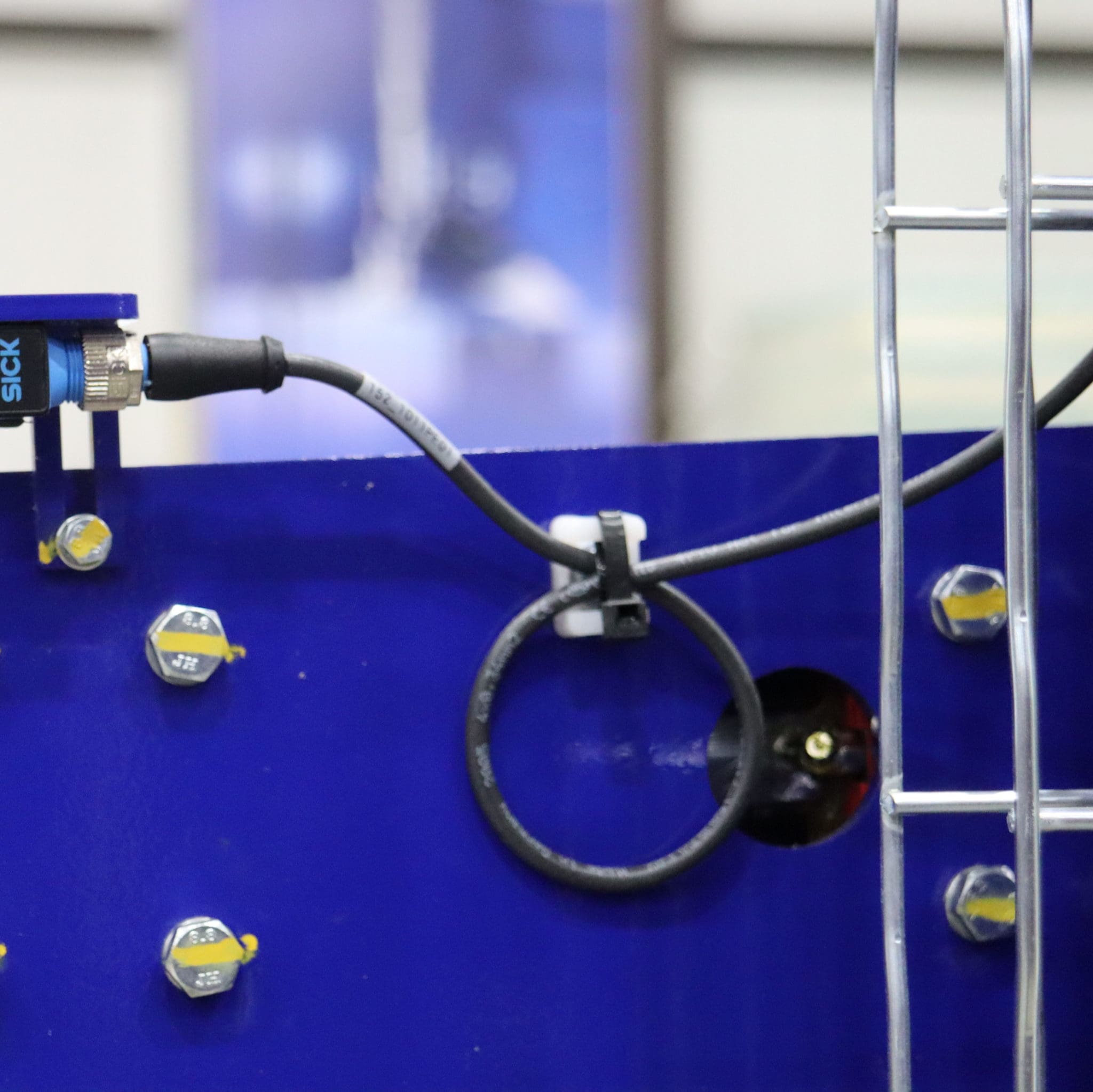

5. Cordset, Straight

Part ID: 01-1902147

What It Does: These are the most common cordsets on this machine and are used to power a variety of devices such as photo eyes and prox’s.

How Many On My Machine? Standard cage – 39; Variable cage – 44

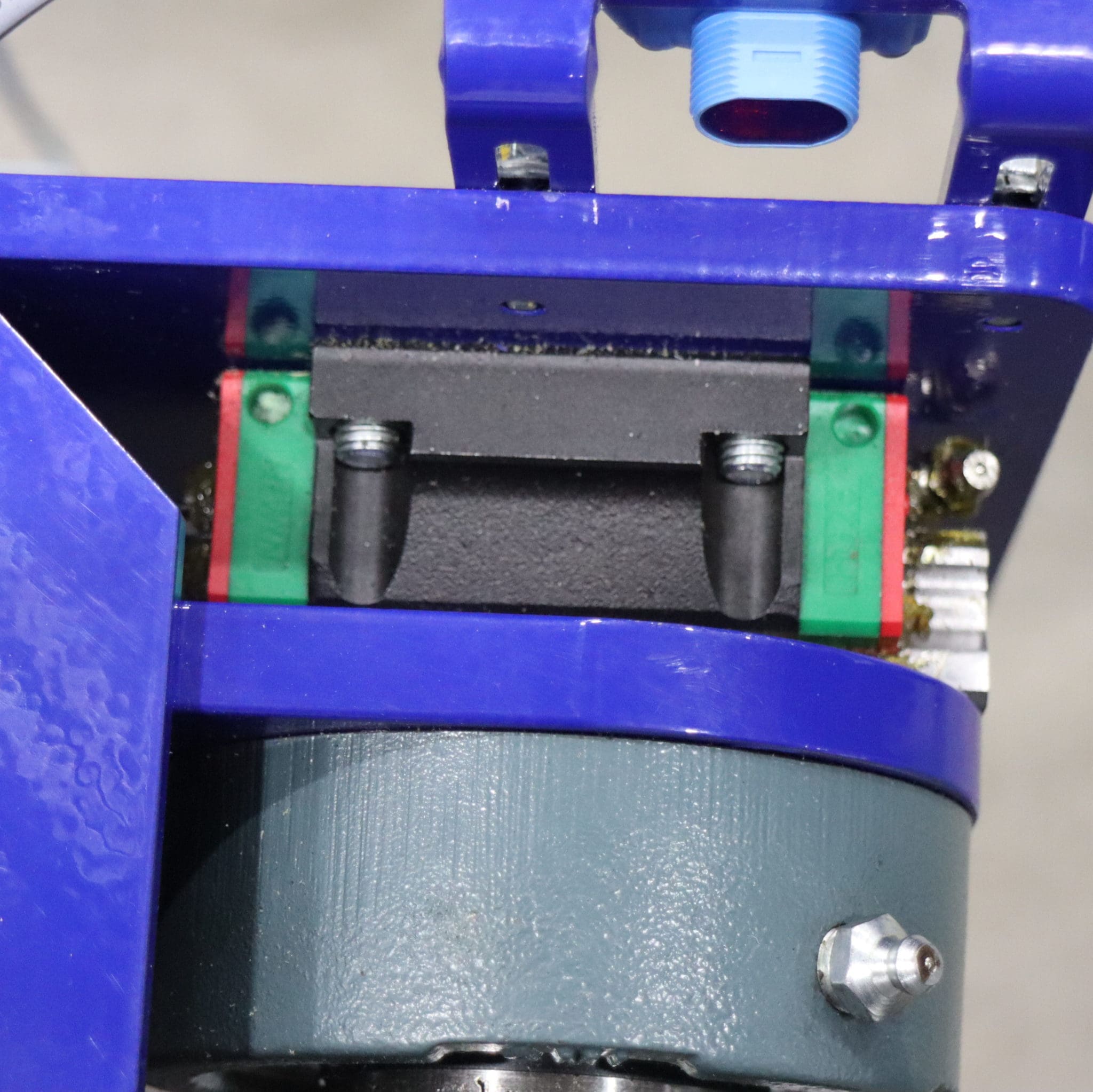

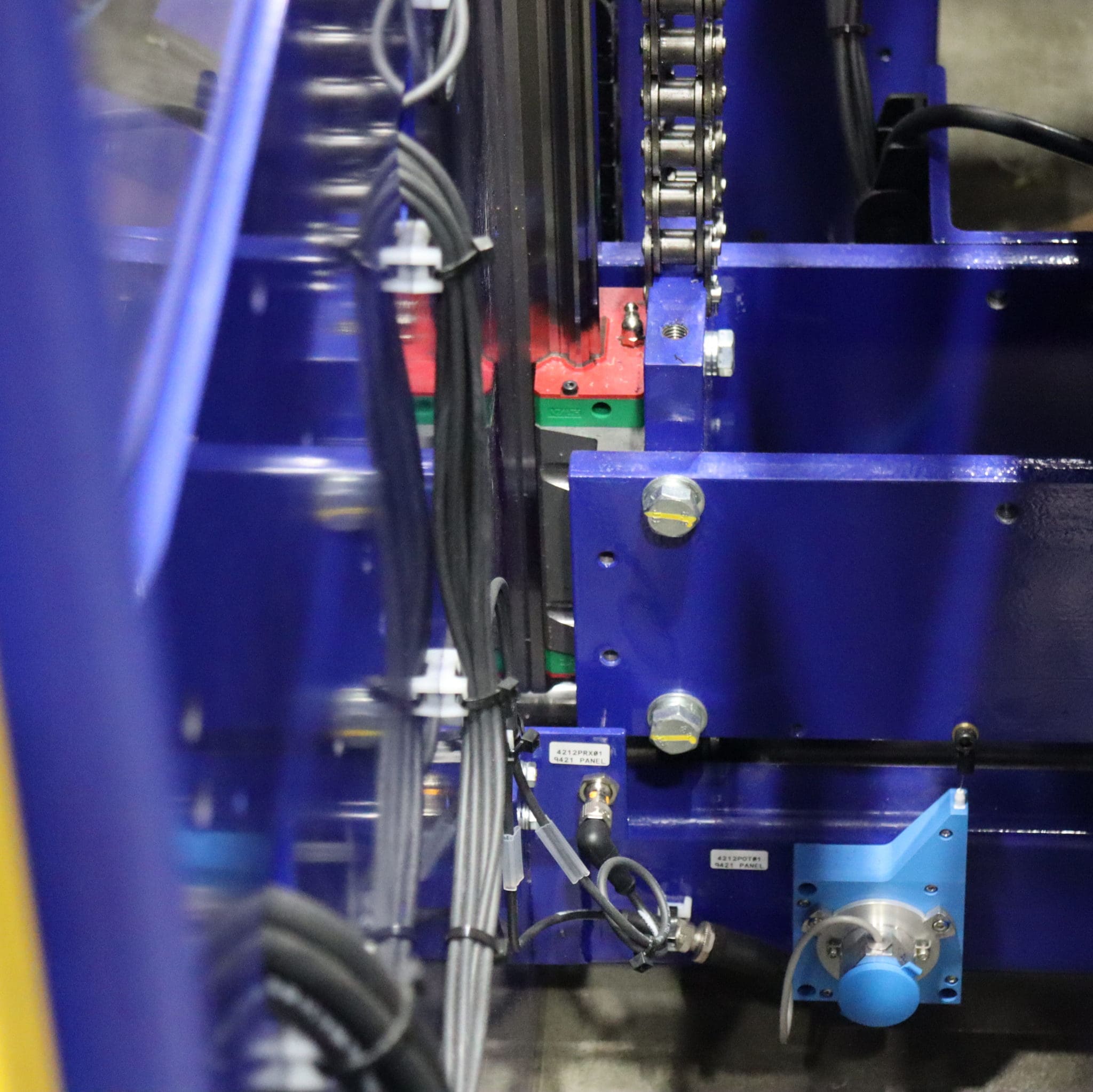

6. Bearing, Linear Ball Cart 25MM

Part ID: 02-0700585

What It Does: This guides the linear movement of the curtain seal bar and the infeed conveyor.

How Many On My Machine? 14

7. Linear Bearing, Cart, 30MM

Part ID: 02-1201277

What It Does: This guides the linear movements of the exit pusher, fold conveyor, traversing stretch cart, and roll cage hatch.

How Many On My Machine? Standard cage – 12; Variable cage – 18

8. Bearing, Linear Ball 45MM HVY

Part ID: 02-1301035

What It Does: This guides the linear movement of the fold lift and the fold bar.

How Many On My Machine? 4

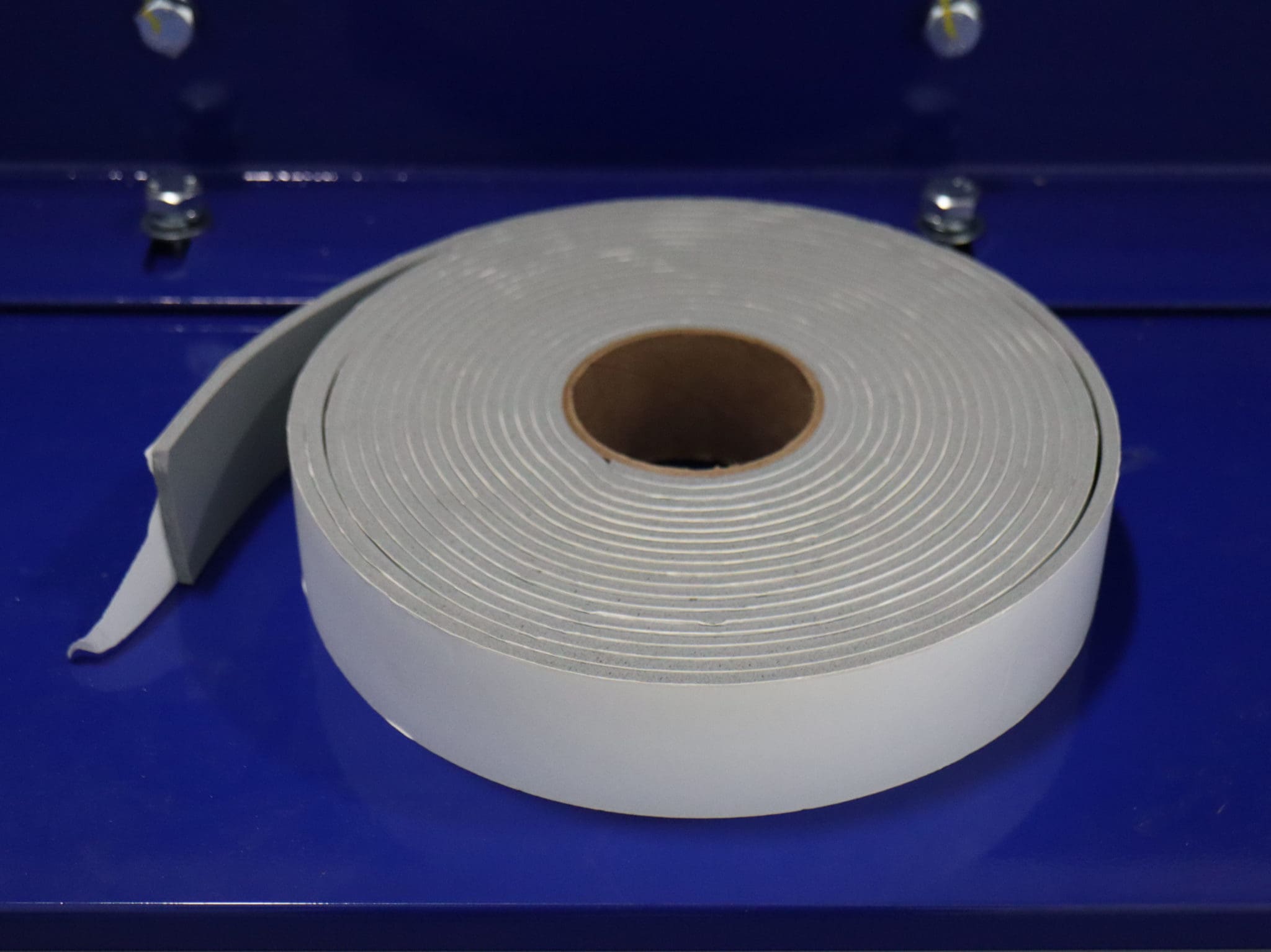

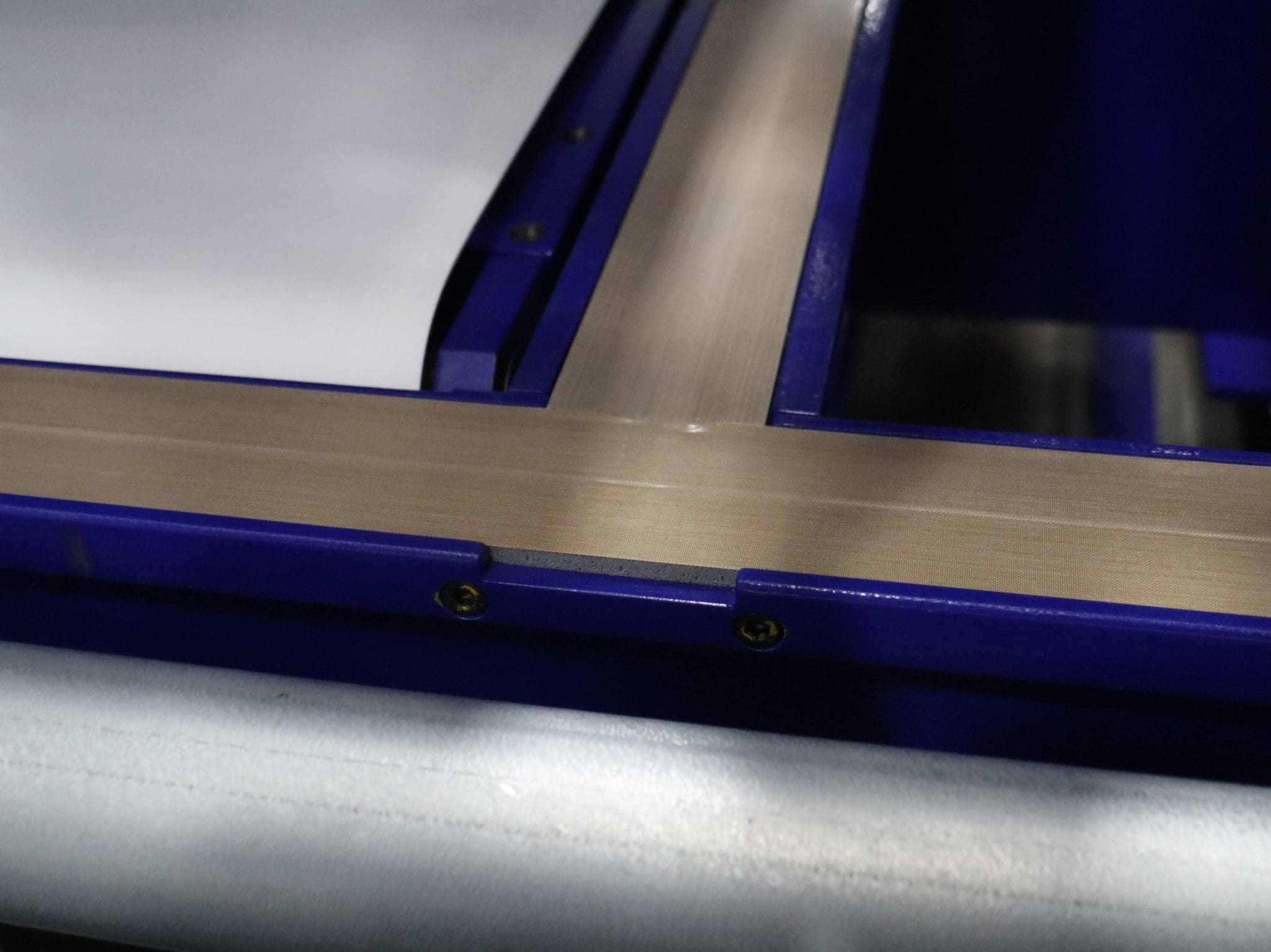

9. Gray Silicone Foam

Part ID: 02-1600161

What It Does: The silicone foam provides a cushion for the seal bars to press into, protecting them from dings, scuffs, and other wear and tear that would occur from sealing against an otherwise hard surface. The foam is designed to withstand high temperatures.

How Much On My Machine? 25 feet

10. Heatseal, Teflon Tape

Part ID: 02-1400120

What It Does: The teflon tape is the surface the seal bars seal against. It prevents the film from sticking to the anvils. The tape is applied on top of the gray silicone foam.

How Much On My Machine? 25 feet

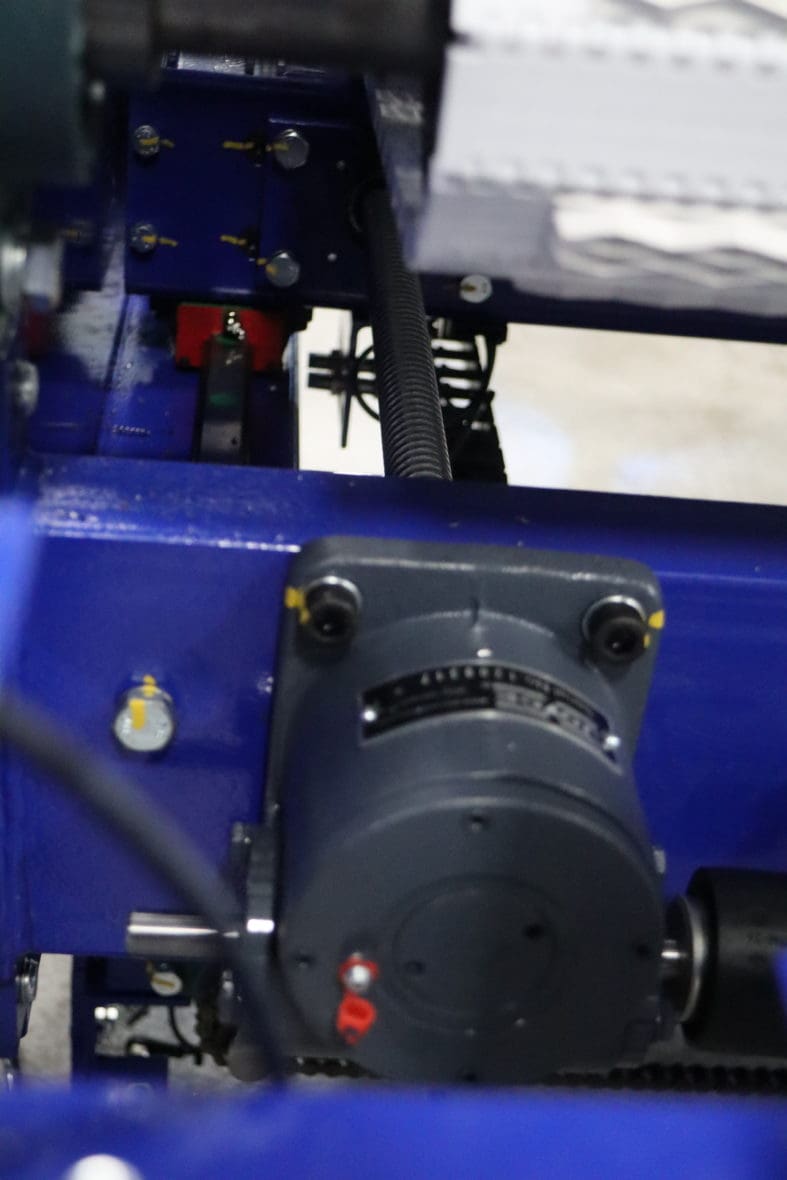

11. Screw Jack, 3 Ton

Part ID: 02-1401278

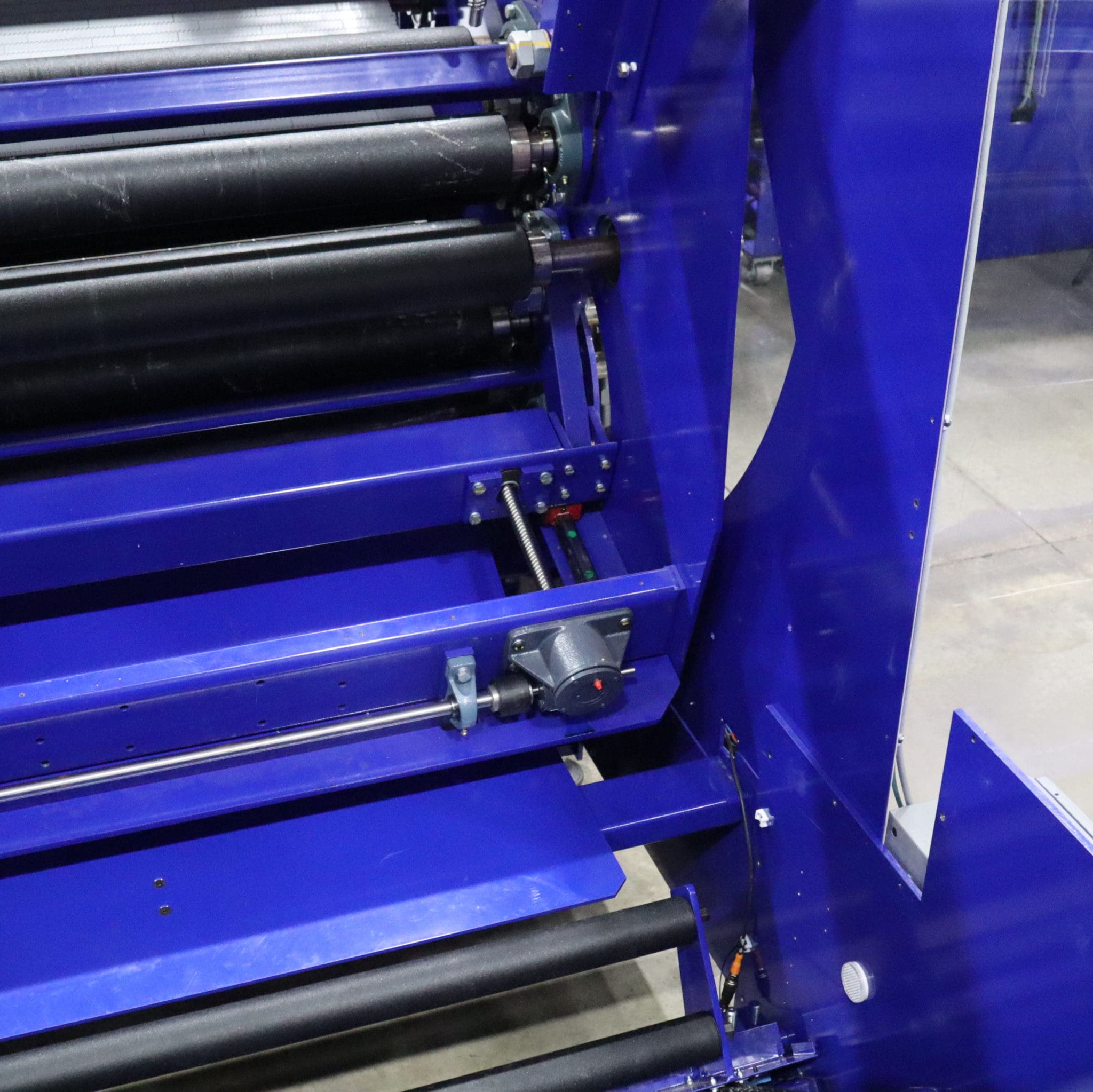

What It Does: Two 3-ton screw jacks work together to open the roll cage hatch and release the product.

How Many On My Machine? 2

12. Screw Jack, 2 Ton

Part ID: 02-1600766

What It Does: There are three sets of 2-ton screw jacks on each variable roll cage: one set of infeed ball screws, one set of upper hatch ball screws, and one set of lower hatch ball screws. These screw jacks work together to adjust the roll cage diameter.

How Many On My Machine? 6 on a variable cage only.

13. Poppet Valve

Part ID: 02-1700636

What It Does: Poppet valves are inside the blocking valves and control the blocking valve to let oil through.

How Many On My Machine? 4

14. Proportional Valve

Part ID: 05-1700095

What It Does: The proportional valve controls the hydraulic cylinders to raise the tamp. The speed of the tamp can be adjusted by changing the valve opening.

How Many On My Machine? 4

As you approach the end of the year, spending some of your remaining maintenance budget on spares will be an investment into the following year if they go unused. Be sure to also check with your account manager if you have film rewards you can put towards parts orders through our Partnership Program – a great perk for clients purchasing C3 consumables.

These 14 parts are by no means the only spares you should have on hand. C3 supplies a recommended spares list with all our machinery upon installation. Be sure you’re familiar with these recommendations and prepare accordingly.

Want to order some or all of the parts you see here? Contact us and someone from our Service team will follow up to get them shipped to you ASAP.