Over the past decade, the bedding market has changed dramatically. Consumers are no longer satisfied with a one-size-fits-all solution — they’re looking for a better sleep experience that balances support and comfort. That’s where hybrid mattresses come in. They’ve quickly become a popular choice, thanks to their ability to suit a wide range of preferences and sleeping styles.

But while hybrid designs offer big benefits for consumers, they bring real challenges to manufacturers. Combining multiple materials into one mattress demands precision, seamless integration, and strong, consistent bonding. Traditionally, this has meant labor-intensive processes that often lead to:

-

- Frequent downtime for maintenance and manual adjustments

- Safety risks tied to heavy lifting and repetitive motions

- Inconsistent quality, which can increase scrap and erode customer satisfaction

Meet the LCN 1250 FE: Built for Hybrid Manufacturing

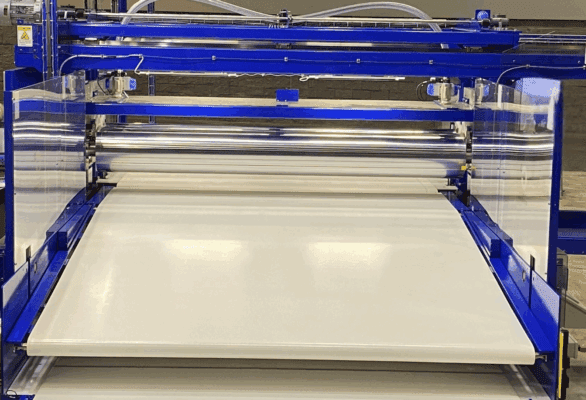

C3’s LCN 1250 FE was designed specifically to tackle these challenges. “FE” stands for Foam Encased — the common hybrid configuration where foam rails wrap around an innerspring unit, forming a tub-like structure before additional foam layers are added. This approach boosts edge support and overall stability, both of which are high priorities for buyers.

Consistency You Can Count On

The LCN 1250 FE features a precision squaring system and automated conveyors that deliver base foam and allows operators to place the perimeter rails with pinpoint accuracy. That means

-

-

- Rails align perfectly around the coil unit

- Each mattress maintains its exact dimensions and structure

- Less manual input, more consistent quality

-

With its guided containment conveyor, operators can build foam encasements faster and with far fewer alignment issues than in manual setups.

Less Downtime, More Flexibility

Manual assembly often leads to stops and slowdowns, whether to fix an alignment issue or adjust glue flow. The LCN 1250 FE helps keep things moving with:

-

-

- Automated squaring and containment to reduce operator adjustments

- Shuttle-fed coil loading for faster placement

- Hot melt glue capability for precise, mess-free bonding

-

Manual assembly often leads to The result? Shorter cycle times, fewer maintenance interruptions, and smooth transitions between mattress types — all without sacrificing quality.

A Safer Work Environment

Handling large foam components and coils by hand isn’t just slow; it’s risky. The LCN 1250 FE minimizes those risks with:

-

-

- Automated conveyors that manage heavy lifting

- Fewer manual positioning steps

- Cleaner, safer glue application

-

By reducing physical strain on operators, the system not only speeds up production but also helps protect your team.

Better Bonding for Better Quality

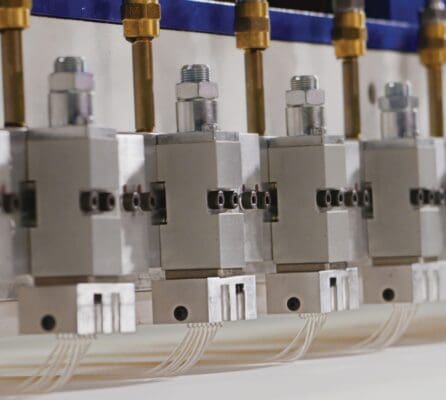

In hybrid builds, strong, even glue application is critical. Poor bonding can lead to layer separation and early wear — problems no one wants. The LCN 1250 FE’s advanced hot melt system replaces traditional hand spraying with:

-

-

- Even, consistent glue coverage

- Minimal waste and overspray

- Reliable, long-lasting bonds

-

Because the process is semi-automated, it removes variability caused by fatigue or inconsistent technique, which means higher-quality finished mattresses, every time.

Ready for What’s Next

One of the LCN 1250 FE’s standout features is its flexibility. Manufacturers can easily switch between all-foam, innerspring, and hybrid models without needing separate production lines. The modular design lets you adjust glue manifolds and containment walls (and remove some components) on the fly, making changeovers quicker and expanding your production capabilities.

As demand for hybrid mattresses continues to grow, manufacturers need smarter ways to boost output, maintain consistent quality, and reduce physical strain on workers.

C3’s LCN 1250 FE helps you do just that. By automating key steps, minimizing downtime, and ensuring rock-solid quality control, it gives you the tools to meet market demand — now and into the future.

Ready to level up your hybrid mattress production?

Reach out to learn more about the LCN 1250 FE and how it can transform your operations.