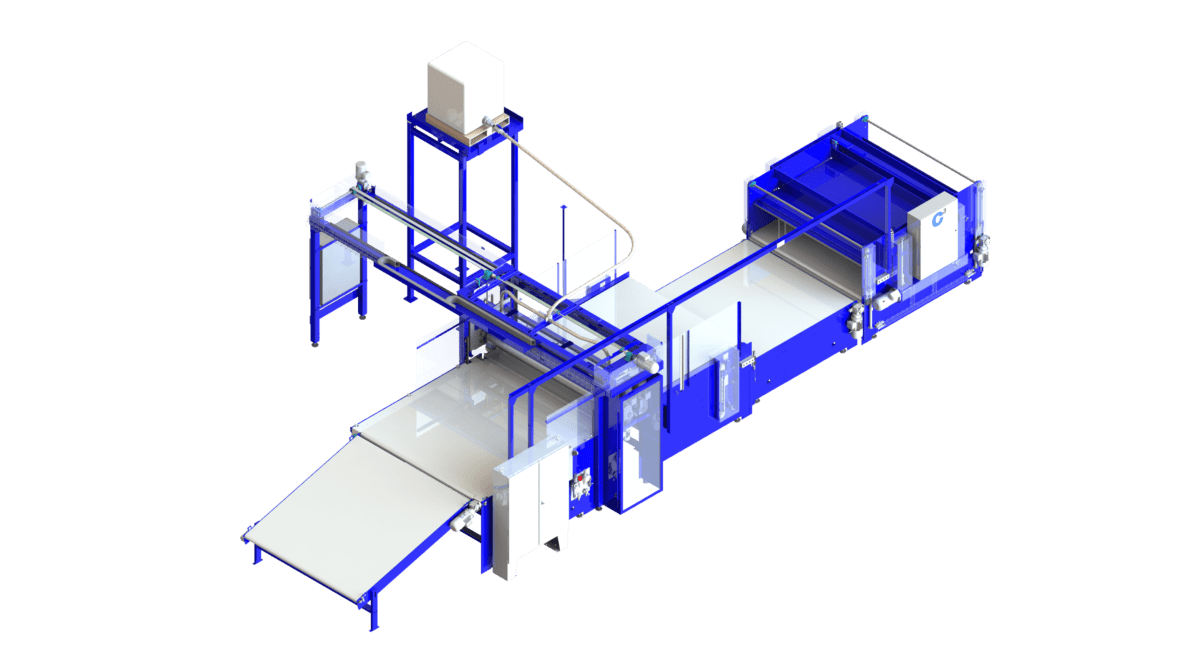

Our R&D engineering team is excited to unveil our newest machine for mattress lamination, the LCN1250 model. It comes to the market setting a new standard for fast throughput (at 7 seconds per layer) and improving ergonomics by eliminating the need for operators to lift mattress layers during the lamination stage of manufacturing.

Installing the LCN1250 roll coating lamination system can nearly double your production rate while reducing the cost to build a mattress when used with water-based adhesive. The added functionality, especially when used with synthetic latex glue, allows for more product to be produced with fewer resources.

We’re excited to launch this new machine for the foam and mattress industry so manufacturers like you can benefit from an easier to use and faster lamination system that will allow you to dramatically enhance your production.

Redefining Throughput & Ergonomic Expectations

Up until today, our standard lamination systems held a pass-through rate of 15 seconds per layer. When using the LCN1250, we halved the pass-through rate to 7 seconds per layer. Why does this matter?

We estimate an average speed of 50 ft per minute when facilities use acrylic glue that must pass through an IR heater or oven. This production rate quadruples on the LCN1250, going to 200 ft a minute with the use of any water-based adhesive. That compounded over time equates to hours of time savings thanks to the LCN1250 which means you’ll be able to produce more without changing anything about your production except the machine.

The LCN1250 has more to offer, though. The development of the merge table, or the mechanical conveyor that shuttles layers under the rollers and drops them onto the build, takes all the lifting from the operators. Now the operators will only be responsible for quick guiding motions and finger-adjustments at waist-height. When we improve the job for the operators at this stage, they’ll experience fewer overuse injuries and you may see less turnover due to labor-intensive duties.

The Fastest Lamination Machine On The Market

At the time of this machine’s launch, the throughput per layer is at 7 seconds. Watching the LCN1250 in person, you’ll see a noticeable difference in throughput when compared with other lamination machinery in the industry.

When we improve the throughput of the machine, we’re able to make more efficient use of a facility’s resources. If the lamination area is producing at a high rate, you can accumulate product for the assembly section. This maximizes your operators’ time as they have a steady feed of product for their shift. It also opens up flexibility in scheduling, as the same operators that run a SKU of product through the lamination machine could then assemble that product after as a batch.

Improving machinery characteristics like throughput or ergonomics gives facilities like yours more options in designing your production and using your resources. The launch of this new lamination system is revolutionary for the foam and mattress industry.

You’ll want to see this in person, so visit us at ISPA Expo March 18 – 20th, 2020 at Booth 100. We’ll have the LCN1250 running live as part of a production line including assembly and packaging.

Can’t make it to ISPA Expo? Visit us at our facility in Appleton, WI for a private demo. Contact us to schedule your visit.