The mattress marketplace is becoming increasingly competitive. Sales are soaring, new brands are emerging, and the already endless list of product options seems to grow daily. In a digital age where it’s never been easier to share a product review, your brand’s reputation depends on customer satisfaction – and achieving customer satisfaction starts with knowing your products. Especially now, in a time where many facilities are over capacity or seeing workforce constraints, knowing what products you’re making when, where, and with what resources, is a surefire way to make the most of your production and ensure quality products ship to your customers.

Beyond that, knowing your products inside and out also prevents other costly mistakes. There’s obviously the expense of dissatisfied customers returning their order, but there’s also the delays caused by a confused production team or missing materials. It’s also possible that not taking a close look at your products could lead to purchasing equipment that isn’t right for building or packaging them.

A production specification sheet should be at the foundation of producing consistently remarkable products. We view a spec sheet the same way a chef or baker would use a recipe card. It contains three main sections: ingredients (materials), instructions, and a defined end result. Together, that information aids in establishing standards and consistency between batches (or production runs).

Some of the information contained on a spec is, of course, helpful for inputting machine recipes. But what you may not realize is that having a specification sheet benefits you from the time you choose machinery to when your customer unwraps your product in their home. Here, we’ll cover three ways a spec sheet will influence your product throughout its journey.

1) Machine Selection – Match Your Product To Machinery Capabilities

A prepared spec will go a long way when exploring equipment options. Understanding your product and packaging goals is the best way to determine the right machine for your needs. It can also help your R&D team design products that will suit the packaging process.

Say you’re launching a new product with a goal of roll packing the mattresses without folding them. If you have a spec prepared and share it with our team, that information may lead us to suggest an RC9500 versus the more robust CF1396. In this case, knowing your packaging goal prevents you from over-buying a machine with functionality you don’t want or need.

If you don’t know what your packaging goals are yet and need help determining a product’s compression potential, it’s especially critical to understand the product itself. We use data about your product, like dimensions, weights, and densities of each layer to calculate how your product will respond to roll packaging using our compression calculator. This tool allows us to explore the impact different packaging configurations have on the product, all without ever physically compressing it.

This tool is integrated into many of our packaging systems and not only helps you manufacture a quality product every time, but also aids in the R&D process. Many product development teams will utilize a test run with this technology to determine the best build for the product to reach a specified package goal.

2) Production – Improve Clarity And Establish Standards For Your Team

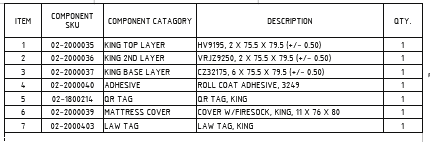

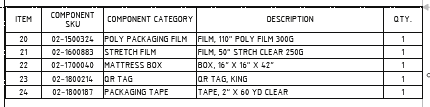

Product specs also play an essential role in making expectations and standards clear to your production team. Let’s take a look at the information found in the right column of our sample spec:

Here we have a bill of materials needed to produce and package this bed. Each item has a SKU assigned, category, and description. The component SKU is derived from our ERP system and clarifies to everyone in the organization what specific item it references.

Going back to our recipe card analogy, this BOM section acts as our ingredients list; the more specific you are about your components, the more you can control the final product’s quality. Suppose you sent someone to the store to pick up ingredients for making cookies. They’d likely come back with very different groceries than if you had sent them to get specific ingredients for gluten-free white chocolate macadamia nut cookies. If you have precise expectations for the materials needed, a spec sheet clarifies them to everyone from your purchasing department to your materials handlers and machine operators. Using component SKUs or catalog numbers along with descriptions ensures everyone in the organization speaks the same language when it comes to the required materials.

The instructions column is equally helpful to your production team if you’re running various products and packaging types. For example, the ideal way to run a fold-and-roll queen bed on our CF1396 would be to lead with a 60-inch edge and fold along the 80-inch length. However, an auto-bagged queen would enter into the tamp section 80-inch edge first to save on poly film. Documenting details like this gives your operators a reliable place of reference for all SKUs you produce and reduces confusion between changeovers.

3) The Customer Experience – Delight Your Customers With Consistent Quality

Your customers will likely never see a copy of your production specs, but this document matters now more than ever to ensure their satisfaction.

With online bedding sales rising and many shoppers opting for an online buying experience due to COVID-19, your one chance to “Wow” customers with your product is when it’s already on their doorstep. If your production team follows the spec, your customer receives exactly what they ordered.

Not only do production specs decrease the odds of manufacturing errors, but they also ensure your efforts to delight your customers are by design. Think about the process of unboxing a mattress – what makes it seamless for the customer? Things like compressing the product with the top up before folding means the customer will not have to flip the bed over once it’s open. What would make it more difficult? A product wrapped at the wrong diameter could result in a mattress that’s too snug inside the box, making it tricky to remove. Including details like these in your spec helps ensure your customer has a great experience with your product from the moment it arrives.

Product specs also help with tracing. If the recipe is tied to a SKU, the spec information can be tied to each product’s label using RFID labeling. When integrated into the line, each bed is tagged with this information. If returned or experiencing issues, the bed can be traced to the lot number and it’s easier to determine the cause of the return – whether a manufacturing issue occurred or if it was simply customer preference. This data in sum also makes any manufacturing issues visible so you can identify them and resolve. It’s much harder to do this if there is no standard in place!

Whether you’re looking to purchase new manufacturing equipment, clarify your goals to your team, or enhance your customers’ satisfaction, documenting what you want to make is the best place to start. Now is the time to implement production specs for your products or review your existing specs. Learn more in Issue 5 of Eng*nuity Magazine, where we share a four-step process (plus a bonus step) for developing specs focused on building the perfect bed, every time.