What to consider when pivoting your retail business.

As millions lay their heads down to rest tonight, they’ll likely be sleeping at home thanks to the surge of the COVID-19 pandemic. For weeks now, people have been under safer at home orders and staying home, meaning they’re spending more nights sleeping in their own beds than ever before. If they didn’t like their mattress before this crisis, they’re surely looking for a new mattress now.

Early predictions are showing an increase in mattress sales over the next few years, pointing to COVID-19 as fueling that growth. There’s a glaring disclaimer to this growth, however, as it is projected without the normal operation of retail storefronts. If customers can’t visit stores in person, where are the sales coming from?

Here’s a hint:

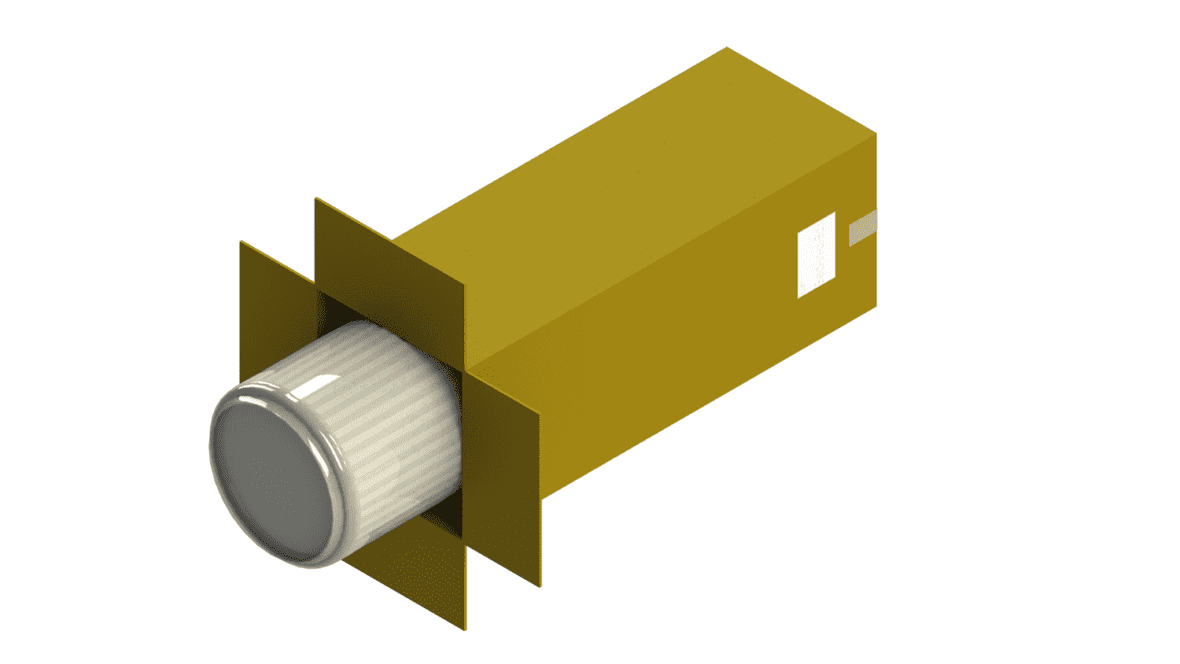

A packaging solution that was originally called a mass disruptor of the mattress industry a few years ago is now resurging again with the same title. In a new world where online shopping is the only shopping allowed or that consumers are comfortable with, mattress manufacturers who have the capacity to ship direct to consumers are seeing earlier surges in production and sales than those who don’t have the compression technology to do so.

Even as the economy reopens, retail will not resume business-as-usual. Restrictions may be lifted, but consumer confidence to enter into stores to shop may remain low. No doubt the traditional retail landscape for mattresses – where customers can lay on mattresses and try them in person – will have to change.

Mattress manufacturers must pivot, and pivot fast, to meet their consumers where they’re at – which is now at home, sleeping on an old mattress they can’t stand anymore.

Analyzing these changes to the market’s product fulfillment, we revisit three considerations when shifting a retail distribution channel to an online channel. C3 has helped many companies burst into selling via e-commerce with our roll packaging technology. Here is the framework by which we consult companies to get their product to ship directly.

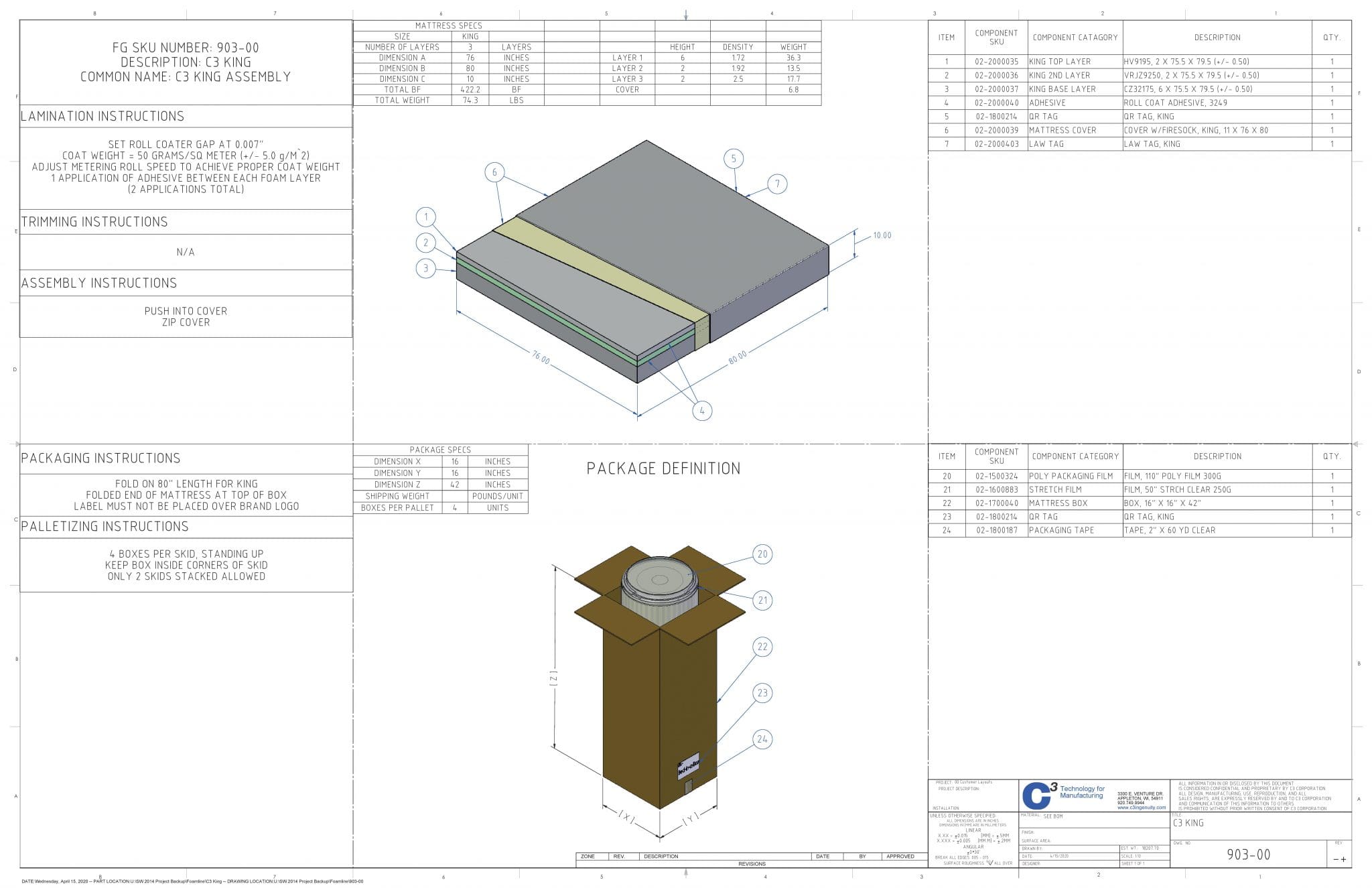

1. Build Your Product Specs

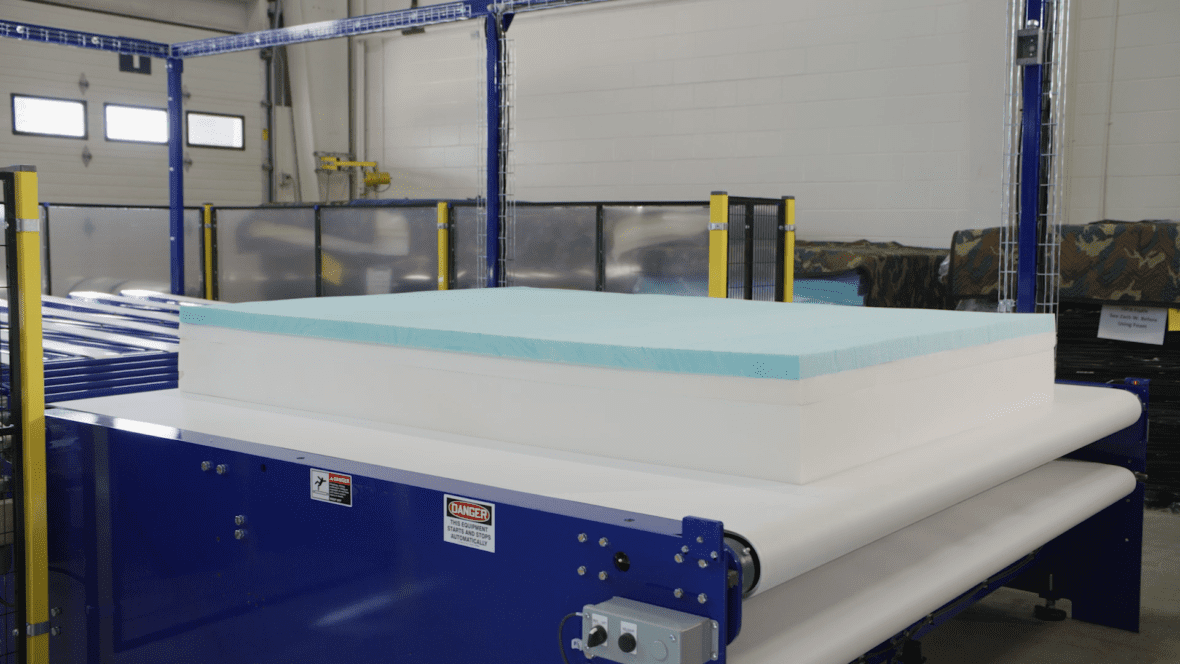

Consistency in your products is more important now than ever. As customers order more beds online, their first hands-on interaction with your product will be when it’s already in their home. How do you ensure that the product they received meets their expectations?

The key to your customer knowing what they are getting is for you and your team to know exactly what you are making. At C3, we believe the best way to establish and communicate expectations is to start every production run with a product specification sheet.

We think of specs like a recipe card for chocolate chip cookies. Recipe cards have three sections:

- Ingredients

- Instructions

- End result

Most manufacturer’s know what their end result is. For example, you may know you need to run 200 King-sized, 3 layer beds. Instead of only passing along the end result to operators, you can better control what they make if you also share with them a spec sheet that explains the “ingredients” (raw materials) and instructions that complement them. Follow the three recipe-building steps in order to build a usable spec sheet:

1. List the Ingredients – Your Raw Materials

Before you can begin baking, you need the right ingredients, in the right quantities. For example, raisins are not an acceptable substitute for chocolate chips, and a teaspoon of salt is not the same as a tablespoon of salt.

Begin building a spec sheet by listing your “ingredients,” or bill of materials in a similar way. What are each of the layers in the build? What are their dimensions? Are there any acceptable tolerances? What adhesive are you using? List every material needed to make both your product and the package.

2. Document the Instructions

Once you have your materials together, document how you want the product to be made and packaged. Just as your cookie recipe requires you to mix dry and wet ingredients separately before combining, your instructions for producing your products should be specific and listed in the correct order. This often includes the work that needs to be done through the lamination, assembly, and packaging workstations.

3. Identify an Acceptable Finished Good

Lastly, establish and document quality checks for the finished product. Are the dimensions right? What about corner-to-corner measurements? Your customers are expecting a rectangular bed and not a parallelogram. Was the product folded evenly before it was rolled? If not, it could look careless or not even fit properly in the box.

Once you have your specs written out, you can distribute them to your operators just like you might share a copy of your cookie recipe with a friend. They can now perform checks and abide by specifications for each check.

Not only are these specs critical to controlling the quality of your products, but they’re also necessary for determining the compression packaging possibilities.

2. Determine Your Products’ Compression Capacity

Why is it essential that we gather spec information and take the time to do this first? Because the real question isn’t so much if you can compress your mattress products, it’s if those mattresses will recover from compression.

If you were to take your beds, start compressing them, and then ship them directly to your customers without first checking the viability of this, your customers could end up unrolling a bed that won’t ever bounce back before they’ve even had a night’s sleep on it. (That is, if you didn’t end up damaging the machine first!)

This is where having a written specifications document for each of your products is important. We look at what you are starting with by asking questions like:

- What are the product’s dimensions?

- Is it an all-foam bed, or one with a pocket coil base?

- How heavy or dense is each layer of foam?

- How many layers are there?

Each factor affects not just whether a bed can be compression packaged, but also to what final dimensions. By using spec data about your product, we can run calculations and explore safe packaging options without ever seeing your raw materials. The good part is, now that you already created a spec sheet in Step 1, these questions are much easier to answer.

3. Pick a Package To Match Your Spec

When you have a spec and have worked to determine that the product can handle compression packaging, you’re on your way to pivoting from retail to direct to consumer in an efficient manner. Now you can determine what package you’ll use for your final good.

Imagine during this stay at home period you live in an apartment complex. When you run to the lobby to get your mail, a boxed mattress awaiting one of your neighbors catches your eye. “Huh,” you say, “I’ve been curious about buying a mattress that way, too. What brand is this one…”

Packaging matters; and not just because curious neighbors want to see what others buy. Packaging showcases your brand, protects your product in handling, and becomes an interactive experience for customers.

When your business shifts from selling via storefront to online sales, customers are no longer interacting with your product first – they’re interacting with the packaging first. There are aesthetic factors that matter like graphics and branding, but from a manufacturing perspective, the package needs to be created in a way that’s easy to handle, keeps the product in pristine condition, meets shipping standards, etc. It also needs to use packaging materials minimally so the consumer isn’t left with garbage bins full of trash.

Here are a few questions you can ask when determining the ideal packaging parameters:

- What size package does your customer expect?

- What size is easiest for them to handle?

- How much material will keep this product wrapped securely? Will it still be secure on arrival?

- Does the way the product was boxed or bagged make it easy to unpack?

- What packaging materials are needed and how much? Are they recyclable?

Ultimately, the consumer will determine if the packaging is acceptable or not, so it’s important to make a good first impression. Damaged boxes without branding, excessive use of packaging film, or poor product recovery can lead to negative reviews that will mar your brand and lead to high return rates. Consider carefully how to make the unboxing experience as simple and customer-friendly as possible.

These three considerations will help you recognize opportunities within your business to quickly pivot to e-commerce driven sales. With the state of the world changing daily, the ability to identify the parts of your operations that are easiest to transition from retail to online will help your business minimize the lost sales potential from your retail sectors. Contact C3 today to learn more about the process and how we can help you evolve your manufacturing during this time.